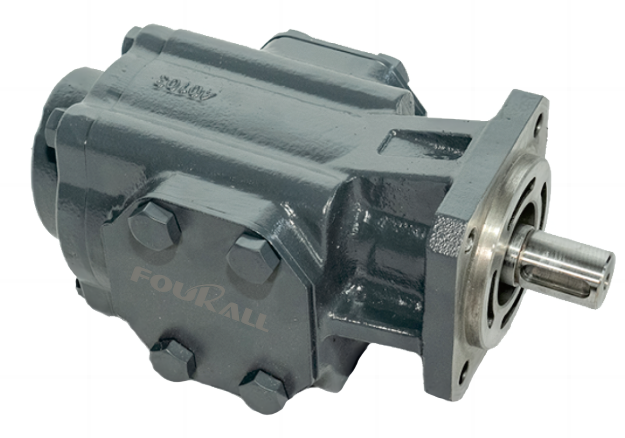

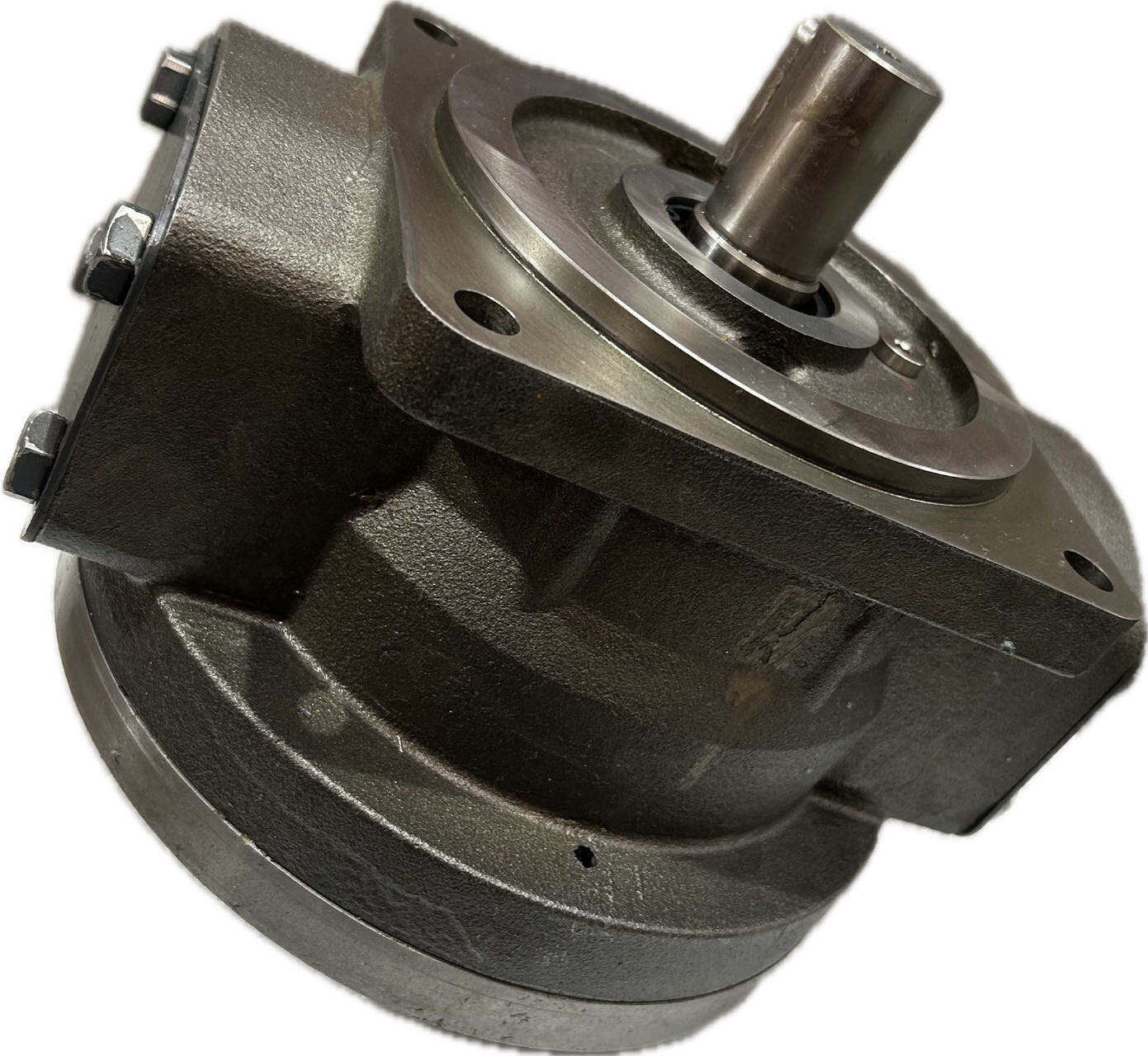

After-sales Service for Wind Turbine Fluid Products

Based on the in-depth analysis of the problems of lubrication, cooling and filtration system for wind power industry and rich experience in implementation, Fourall company’s technical team can provide customized technology and upgrading solution.

Description

Based on the in-depth analysis of the problems of lubrication, cooling and filtration system for wind power industry and rich experience in implementation, Fourall company’s technical team can provide customized technology and upgrading solution.

1.Doubly fed Induction Generator system problem solution:

| Problem Points | Solution |

| Failure of temperature control valve in lubrication system and over-temperature shutdown. | Maintenance free temperature control valve solution. |

| Over-temperature caused by attenuation of cooling capacity of air cooler. | Air cooler over-temperature solution; Anti-sand wind cooler and over-temperature solution. |

| Hose aging, unreasonable layout, leakage problems. | Optimization design and replacement of pipeline layout. |

| Blockage alarm due to low filtration efficiency or insufficient contamination capacity of filter element. | Efficient filter element replacement solution. |

| Gear box oil cleanliness is not enough. | Gearbox off-line filtration solution. |

2.Direct-drive Generator system problem solution :

| Problem Points | Solution |

| Instability of pressure in storage and operation of water cooling system and frequent water replenishment. | Converter water cooling system pressure stabilization (water supplement) device solution. |

| Over-temperature caused by attenuation of cooling capacity of air cooler. | Air cooler over-temperature solution; Anti-sand wind cooler and over-temperature solution. |

| Failure of water cooling system temperature control valve. | Transformation scheme of three-way valve of frequency conversion water cooling system. |

| Hose aging, unreasonable layout, leakage problems. | Optimization design and replacement of pipeline layout. |

| High humidity of frequency converter, poor ventilation. | Converter dehumidification and ventilation reform plan. |

EN

EN

AR

AR

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TR

TR