Ever wondered how machines operate? A large machine like a crane at work on the site, or perhaps seen massive tractors working in the fields of an Acres land. These machines are everywhere with that in them: . Since these two parts are closely working together as a team to make the machine move, dig or do other important duties helping us every day.

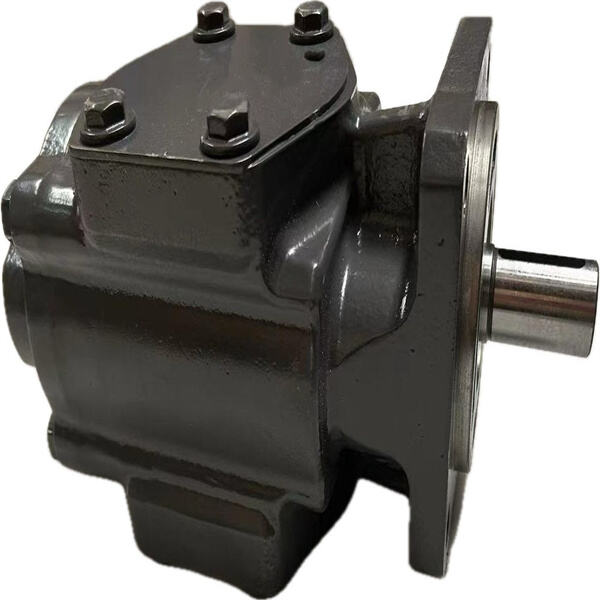

The pressure gear pump are a pair of special parts that fall into the category known as hydraulics. In that case, they are merely using some kind of fluid (usually oil) to facilitate ease in a mechanical process. A gear pump is a Tech with teething spinning wheel more like bicycle gears. When it is spinning around, its listens a bit of oil from places to the other like we move water out one cup and pour into another. Radiating spokes are the teeth, and this gear is also trying to turn in reverse------+osph spoke_modeologie_spoke-round_matchedminus_rotategearmotor+. An oil assists the wheel in its motion by flowing through a motor. This spinning action causes the machine to move and perform work like lifting heavy items or sliding into the earth.

The lovely thing about gear pumps and motors is that they are very reliable. It is why they can operate smoothly for many years without going wrong. That kind of work by people also often depends on their machines, and they need to keep going because the jobs are important. In addition to being high performing, they work very efficiently and don't waste much energy. It is due to this very reason since machines that consume a lot of energy may incur large running costs. If anything else, imagine having to gas up about a million times. That'd cost some dough! We can see Gear Pumps and Motors in many of the machines we encounter on a day-to-day basis, things like construction equipment to farming tools or even then airplanes which fly high above us!

If you own a machine, and this machine requires the gear pump & motor then you have to choose one straight away. You can compare it to selecting the appropriate tool for a particular job. Consider what the machine has to do and how much power it needs doing so. An example of this would be a large excavator that will dig deep holes into the ground, thus needing more robust gear pumps and hydraulic motors compared to what is needed for a small lawnmower which only cuts grass. You should also consider how much oil the pump and engine is really likely to require lubricated correctly. They may get delays in working or eventually, stop function if the oiling is less. Equally, if there is too much oil the pump has to do more work and uses energy unnecessarily — which also isn't ideal!

Gear pumps and motors, like any other machinery, must be maintained or repaired if malfunctions occur. You need to regularly check your oil level and the state of cleanliness (how fresh or old it is) Now is the time to top up or, if it appears dirty and requires refilling, change your oil so that everything goes smoothly. You also have to take the tooth wheels and simple khaki pants clean with no soil or rotten trash If the pump starts to make unusual noises or if you feel it vibrating, this is a good indication that something might be wrong. You should call a mechanic to repair things like that before they get worse.

Hydraulic systems help machinery operate and gear pumps (motors are another type seen in hydraulic equipment) is one of them. There are many other kinds of pumps and motors, moving oil in different manners. A piston pump is a perfect example — it operates much like an enormous syringe, with a moving piston that forces the oil through. A vane pump acts like a spinning door as it turns in order to move the oil across. Depending on the type of machine, each hydraulic systems also has its strengths and weaknesses. Therefore, the selection of an appropriate approach stands paramount to ensure that machines are performing up-to-the-mark.