Cooler Components

- Made of stainless steel, stamped and assembled into shape;

- High heat exchange efficiency, minimal heat loss, and low pressure resistance;

- Plate heat exchangers are detachable for cleaning; brazed heat exchangers are compact with strong spatial adaptability.

Description

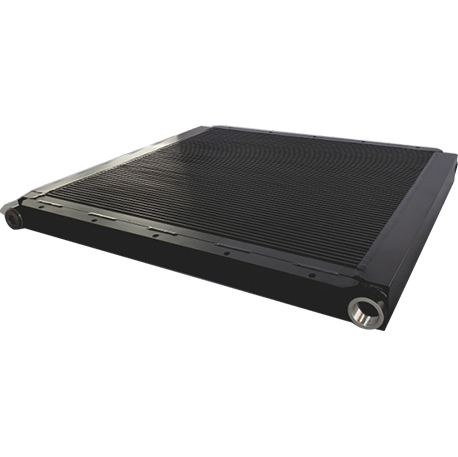

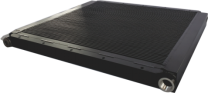

1. Aluminum Plate-fin Heat Exchanger

Function and Characteristic:

The air cooler designed with new structure and high quality anticorrosive heat transfer material can effectively increase the flow channel area, reduce the flow rate and reduce the wind noise. The special technology of welding stress elimination of welding materials of different thickness can meet the fatigue life requirements of extremely low and extremely high temperature environment conditions and achieve better heat exchange effect.

The core body is made of aluminum alloy, and the internal design is interlaced with two flow channels, respectively the hot side flow channel (to be cooled liquid flow channel) and the cold side flow channel (cooling air flow channel). Two kinds of media are heat exchange in the heat dissipation core body for heat dissipation cooling.

Application:

• Used in environmental testing equipment, laser equipment, dry cleaning machine supporting condenser, heater, cold pump, heat pump coil;

• For wind power, photovoltaic, energy storage and other new energy industries, as well as the automotive and aviation industries;

• Heat exchangers for air separation equipment;

• Used in petrochemical ethylene plant, ammonia plant, natural gas liquefaction and separation plant;

• For deep and low temperature hydrogen, helium, refrigeration, liquefaction and other equipment, as well as superconductivity and space technology equipment;

• For refrigeration and air conditioning.

Technical Characteristics:

Suitable for small and medium-sized heat dissipation environment; High heat transfer efficiency: Compact structure: Strong adaptability.

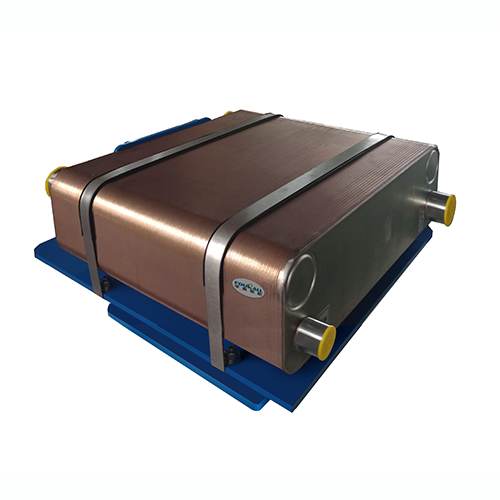

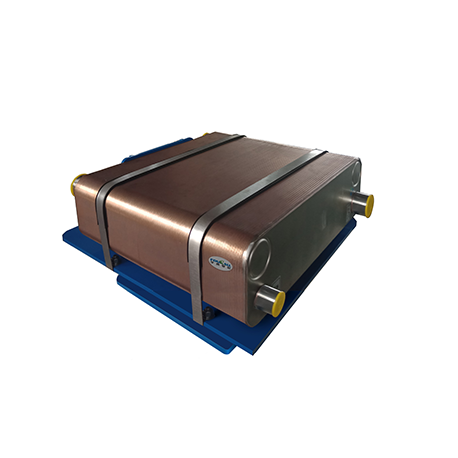

2.Brazed Plate Heat Exchanger

Product Specifications:

|

Operating temperature range: |

-160℃~225℃ |

|

Operating temperature range: |

Vacuum |

|

Maximum operating pressure: |

2.5MPa(water)、3.2MPa(refrigerant) |

|

Single channel volume: |

0.4L |

|

Maximum water flow rate: |

105m³/h |

|

Circuit combination form: |

Single / double circuit |

Function and Characteristic:

A brazed plate heat exchanger is a new type of high-efficiency heat exchanger made by stacking a series of metal plates with certain corrugations and processing them through brazing. Thin rectangular channels are formed between the plates, allowing heat exchange through the plates. Compared to conventional shell-and-tube heat exchangers, it has a much higher heat transfer coefficient under the same flow resistance and pump power consumption. Within its applicable range, it has the potential to replace shell-and-tube heat exchangers.

Product Specification and Models:

HT series

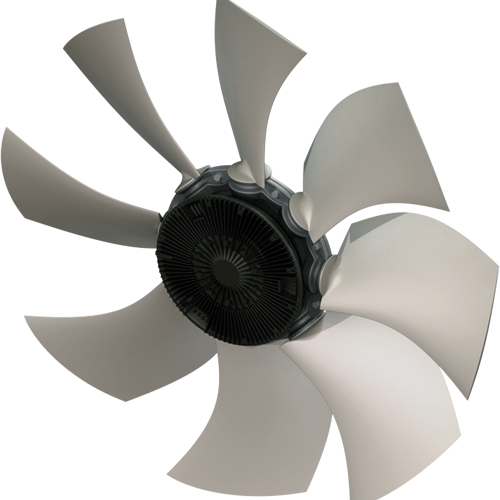

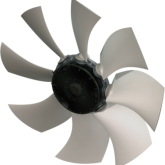

3.Vane Wheel

Function and Characteristic:

One-stop service for windpower components

The company has established a deep cooperative relationship with major wind power component manufacturers, and can provide one-stop spare parts trade integration solution for gearbox customers, wind turbine customers and wind farm owners, saving customers' time and reducing cost. Fourall company after-sale service team provides complete solutions for customers with quick response, high efficiency and cost-effective.

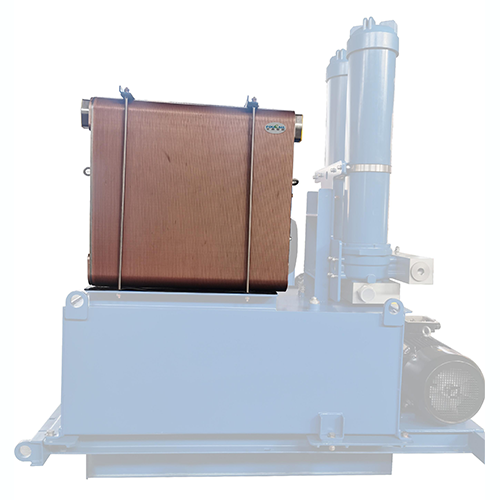

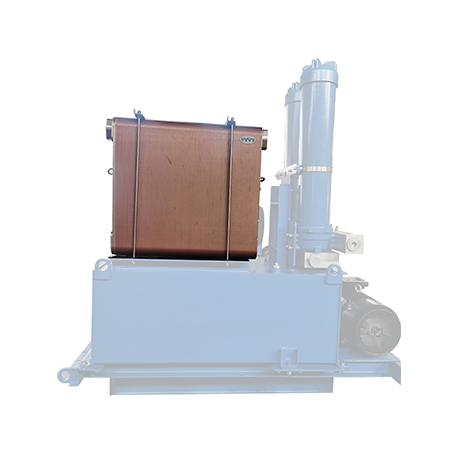

4.Cooling Plate Exchanger

Function and Characteristic:

Cooling plate exchanger is a compact, efficient, and maintenance-free solution suitable for heating, cooling, evaporation, and condensation in various applications. Each product is optimized for specific heat exchange requirements and features a range of unique functions to ensure excellent thermal performance and reliability. It can achieve a long service life even under conditions of extremely high design pressure.

Features:

Lightweight copper-brazed structure with a small footprint;

Better thermal efficiency compared to shell-and-tube heat exchangers of the same class;

Flexible configuration to accommodate various media/fluids for different applications;

Ideal choice for natural refrigerants and low global warming potential (GWP) refrigerants.

EN

EN

AR

AR

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TR

TR