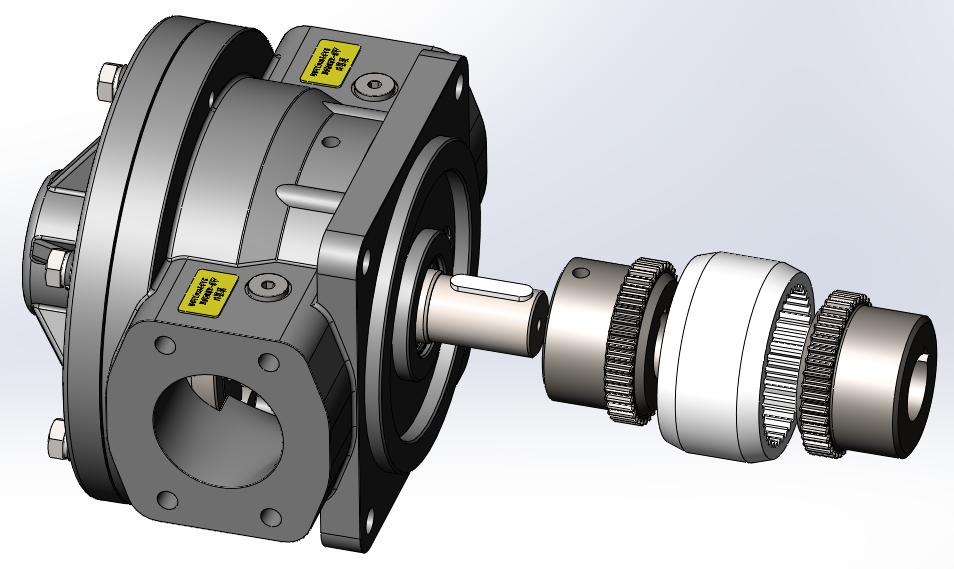

Mechanical Pump

- Excellent performance;

- Compatible with international brand;

- Capable of meeting a design lifespan of over 20 years;

- Smaller shape size to ensure installation interchangeability;

- High precision, low noise, low speed self-priming performance of strong;

- CAM rotor pump structure and high-performance material sliding bearings.

Description

Mechanical pump unique for high viscosity lubricating oil with large pollution capacity, good self-priming performance CAM rotor pump structure and high-performance material sliding bearings, smaller shape size and ensure installation interchangeability, high precision, low noise, low speed self-priming performance of strong, to meet more than 20 years of service life, product series models, through rigorous performance tests, excellent performance.Multiple models are compatible with international brand.

Product model:

FAN40、FAN63、FAN80、FAN100、FAN125、FAN150、FAN180、FAN200

Application:

NGC. Chongqing Geabox, Wangjiang, DHHI. TYHI, Hangzhou Advance gearbox, Flender (Winergy) . ZF, etc.

Product Application Field:

Mechanical pumps, also known as shaft-end pumps, are widely utilized in large-scale mechanical products to convey lubricating oil by utilizing the mechanical output shaft. They find extensive applications across various industries including power equipment, petrochemical equipment, construction materials equipment, shipbuilding equipment, metallurgical equipment, mining equipment, and other general equipment industries.

Product Function and Features:

The FAN series mechanical pumps are cam rotor pumps primarily designed for transporting various high-viscosity lubricating oils. With a comprehensive range of product models, their unique exterior design, protected by national patents, enhances aesthetics and industrial appeal. Compared to similar foreign products, they boast a smaller size and ensure interchangeable installation dimensions. The unique cam rotor pump structure, with a large dirt-holding capacity and excellent self-priming performance, effectively addresses the problem of cavitation in high-viscosity lubricating oils during low-speed operation. The reversing disc automatically switches with changes in the rotation direction of the main shaft, ensuring consistent inlet and outlet directions for lubricating oil regardless of clockwise or counterclockwise rotation. Innovative patented technologies guarantee safe and noise-reduced operation of the mechanical pump. The pump housing is constructed using high-grade cast iron, surpassing foreign counterparts in strength and wear resistance. The gear shaft is made of high-toughness materials, subjected to internal grain refinement and surface hardening treatment, ensuring an exceptionally long service life of over 20 years. Sliding bearings made of high-performance materials offer superior operational performance, further enhanced by oil-friendly treatment during assembly of the bearing sleeve. The FAN series gear pumps undergo rigorous performance testing in accordance with national standards, meeting all design requirements and surpassing various technical benchmarks set by similar foreign products.

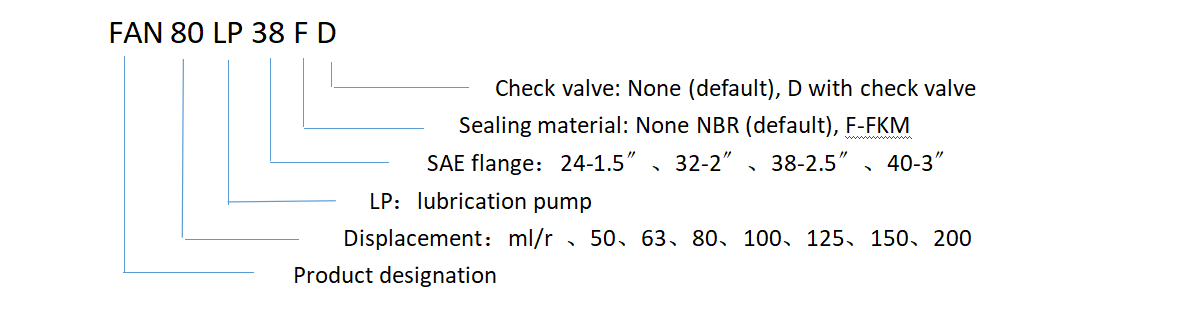

Product model:

Mechanical pump structure:

Model specifications:

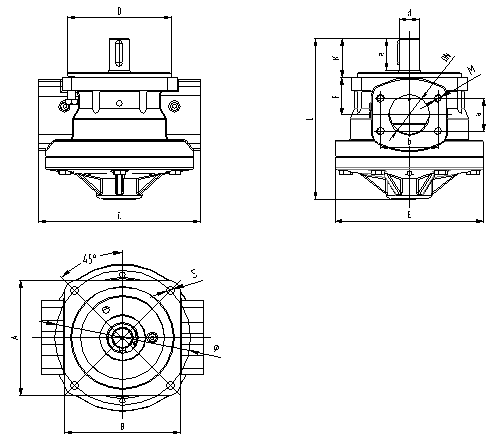

Mechanical Pump Structure Dimensions:

Mechanical Pump Structure Dimensions Table:

| Model | Flange | Structure Dimensions | |||||||||||||||

| SAE | a | b | d | e | A | B | C | D | E | F | K | L | M | S | φ | DN | |

| FA50GLP24 | 1.5〞 | 35.7 | 66.9 | 24 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 230 | 12 | 13 | 210 | 42 |

| FA63GLP24 | 1.5〞 | 35.7 | 66.9 | 24 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 230 | 12 | 13 | 210 | 42 |

| FA80GLP24 | 2.5〞 | 50.8 | 88.9 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 238 | 12 | 13 | 210 | 63 |

| FA100GLP32 | 2.5〞 | 50.8 | 88.9 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 238 | 12 | 13 | 210 | 63 |

| FA120GLP40 | 2〞 | 42.9 | 77.8 | 25 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 192 | 12 | 13 | 210 | 50.8 |

| FA125GLP40 | 2.5〞 | 50.8 | 88.9 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 250 | 12 | 13 | 210 | 63 |

| FA150GLP40 | 2.5〞 | 50.8 | 88.9 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 250 | 12 | 13 | 210 | 63 |

| FA180GLP48 | 3〞 | 61.9 | 106.4 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 250 | 16 | 17 | 210 | 76 |

| FA200GLP48 | 3〞 | 61.9 | 106.4 | 32 | 50 | 178 | 178 | 250 | 160 | 230 | 58 | 61 | 250 | 16 | 17 | 210 | 76 |

EN

EN

AR

AR

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TR

TR