Les composants qui peuvent être les plus critiques pour un système hydraulique sont les vannes de contrôle de débit. Complex NanJing Fourall vanne de contrôle dans le système hydraulique qui transmettent la puissance à travers des liquides, comme l'eau ou l'huile, sont appelés systèmes hydrauliques. Vous en avez peut-être déjà vu dans toutes sortes d'applications, des tracteurs qui travaillent dans les fermes aux pelles mécaniques qui construisent des routes, ou même des avions qui volent haut dans le ciel.

Dans un système hydraulique, il s'agit de la vanne de contrôle de débit ou de la vanne à papillon qui contrôle la quantité d'huile qui sera fait circuler. Cela est vraiment important car cela détermine à quel point la machine s'applique rapidement ou avec force. Plus de fluide est autorisé à passer à travers la machine, ce qui entraîne une plus grande vitesse ou un travail plus intense. Une vanne de contrôle de débit fermée permettrait à moins de fluide de passer, et la machine se déplace alors à un rythme plus lent ou manque de puissance.

L'écoulement du fluide doit être satisfaisant et constant dans les circuits hydrauliques, les vannes de contrôle de débit sont essentielles. Un circuit hydraulique est un ensemble de composants qui fonctionnent pour déplacer et transférer la puissance d'une section de la machine, agissant soit en entrée soit en sortie. Parfois, ces circuits peuvent être simples, et parfois ils peuvent comporter beaucoup de parties différentes en fonction de la machine ou de ce que vous essayez de faire.

Les vannes de contrôle sont utilisées pour réguler et contrôler l'écoulement du fluide, tout en maintenant une vitesse constante et contrôlée. Cet écoulement lent et régulier est crucial, car si les fermetures sont plus rapides ou plus lentes que cette vitesse, la machine pourrait ne pas fonctionner du tout. Si l'écoulement est trop rapide, par exemple, il pourrait également se déplacer un peu trop vite et mettre en danger l'opérateur ou toute personne à proximité. À l'inverse, si le débit est trop faible et trop lent pour être accompli par la machine à une vitesse suffisante afin de ne pas entraver l'efficacité du processus ou ajouter de la latence ; dans ce cas, les tâches humaines prendraient plus de temps.

Il s'agit d'un type de valve à buse. Sa pointe effilée, une fois dévissée, peut être relevée ou abaissée par une série de « clics », vous permettant d'ajuster précisément l'écoulement du fluide. Les vannes à buse peuvent également être trouvées chez NanJing Fourall. système de contrôle de fluide nécessitant des débits relativement faibles, où l'étanchéité est une préoccupation cruciale, typifiée par les cylindres d'échantillonnage et les bouteilles de stockage.

Un robinet de contrôle de débit à compensation de pression est un autre type. Ce NanJing Fourall robinet de commande directionnelle dans un système hydraulique est très ingénieux car il ajuste le débit pour vous, en fonction de la pression entrant dans le système. La vanne s'ajuste afin que la pression varie pour garantir un débit constant. Les robinets de contrôle de débit à compensation de pression sont principalement utilisés dans des systèmes nécessitant de grandes quantités de fluide, tels que les machines de construction très volumineuses ou les équipements lourds.

Les vannes de contrôle de débit sont très utiles pour maintenir les conditions opérationnelles et de sécurité de ces machines. L'entretien régulier est essentiel. Les travaux simples consistent à garder la vanne propre et huilée pour éviter les problèmes. Si votre vanne de contrôle de débit vous pose un problème, au moins maintenant vous savez dans quelle direction chercher pour diagnostiquer le problème. Les vannes de contrôle de débit peuvent souffrir de quelques problèmes courants : elles peuvent fuir et ainsi gaspiller des fluides hydrauliques précieux, être obstruées soit internement soit par un objet externe qui bloque le passage.

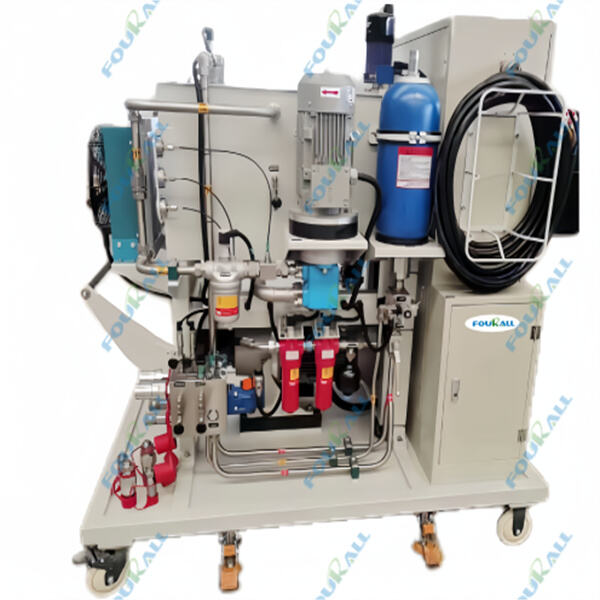

Fourall est un leader dans la technologie des fluides qui propose des produits et services utilisés par de nombreuses industries, y compris l'énergie éolienne, la vanne de contrôle de flux dans les systèmes hydrauliques, les postes de transformation et la transmission d'énergie, les matériaux de construction et les pétrochimiques. Nous concevons et développons des composants personnalisés de refroidissement, de lubrification, des cylindres et des systèmes pour les machines à grande échelle. Nous pouvons offrir des services de soutien technique expert à diverses industries, avec un savoir-faire artisanal et une gestion de qualité. Notre technologie a été utilisée avec succès dans le système de refroidissement des onduleurs photovoltaïques ; le système hydraulique des centrales solaires thermiques, le système de refroidissement du convertisseur SVC dans les sous-stations électriques et le système de refroidissement du convertisseur SVG dans les sous-stations. Fluides de refroidissement et stations d'huile pour les industries métallurgique et pétrochimique. Système de lubrification et système hydraulique pour l'industrie des matériaux de construction, incluant un système de refroidissement.

L'entreprise Fourall a défini une vanne de contrôle de débit dans le système hydraulique de ses produits : produits de lubrification, de refroidissement par eau et hydrauliques pour les applications éoliennes. Le système de refroidissement par eau est conçu pour des applications de grande puissance et industrielles. Les produits éoliens sont divisés en cinq séries qui comprennent plus de 40 spécifications. Ceux-ci incluent la série de lubrification éolienne WD, la série de refroidissement par eau OS, la série d'éléments filtrants FA/HC et des produits brevetés comme le contrôleur de température à suivi de pression de la série FA/D. Nous suivons strictement le système de gestion normalisé SO9001/14001/18001, ainsi que les normes et procédures qui nous permettent de mettre en œuvre une gestion complète de l'information, ainsi que des systèmes de service après-vente verticaux couvrant toute la chaîne, de la R&D marketing, de la R&D, de la fabrication, de la chaîne d'approvisionnement à la gestion de la qualité. Nous pouvons répondre rapidement aux demandes des clients et offrir un service rapide et efficace. Le siège social de l'entreprise est situé à Nanjing, Tianjin et Chengdu, équipé des dernières équipes de vente, de technologie et de service, pour fournir aux clients des produits et une assistance rapides et expertes.

Les membres de l'équipe Fourall sont dédiés à la recherche, au développement et à la production de composants fluides et de produits fluides pour des applications dans le domaine de l'électronique de puissance à grande échelle et des nouvelles énergies. Notre gamme de produits inclut des vannes de contrôle de flux dans les systèmes hydrauliques et les systèmes de refroidissement par air, des filtres, des pompes mécaniques, des pompes à engrenages, des pipelines pour l'huile, des TCVs à suivi de pression et des filtres hors ligne de contournement, etc. L'équipe R&D expérimentée de Fourall, avec sa connaissance approfondie des applications industrielles des fluides ainsi que plus d'une décennie d'expérience dans les applications de produits fluides pour l'énergie éolienne, est capable d'identifier rapidement les problèmes et d'offrir des solutions technologiques. La technologie de traitement avancée de Fourall, associée aux équipements de test les plus récents et aux systèmes de garantie qualité, repose sur des systèmes modernes de test et de gestion rigoureuse de la qualité.

Nous avons fourni des systèmes de lubrification ayant une capacité de 6000 MW, ainsi que plus de vannes de contrôle de débit dans des systèmes hydrauliques de refroidissement par eau. Nous avons également servi plus de 1 000 parcs éoliens ainsi que plus de 300 fabricants d'éoliennes. Nous avons établi une collaboration gagnant-gagnant avec plusieurs grands fabricants de composants nationaux renommés, tels que CSSC, NGC, DHHI, etc. Nous venons de recevoir un système de refroidissement par eau pour le projet offshore de 10 MW du groupe Dongfang Electric Wind Power à Danzhou. Accepté en mars 2024 et livré en avril, 60 unités seront assemblées avant juillet. Les performances avancées et brevetées de dissipation de chaleur dans notre laboratoire d'aérodynamique ont permis cet accomplissement. Ce succès démontre l'engagement de Fourall envers l'innovation et la fourniture de produits et services de la plus haute qualité tout en soutenant les développements mondiaux des énergies renouvelables.