Every factory and manufacturing plant in the world sees a lot of machines that work as products creating tools on daily basis, as well as the NanJing Fourall's hydraulic pump system. These pieces of equipment then need to be looked after in order for them to keep working the way they should be. One of the most crucial ways to lubricate them would be through standard penetrant. Lubrication: Lubrication is the process of applying oil or grease to all moving parts in machine. That will allow the elements slide quick and sleek. The equipment will eventually wear out without the lubricant to keep it running. This is where the alpha lubrication system comes in to help.

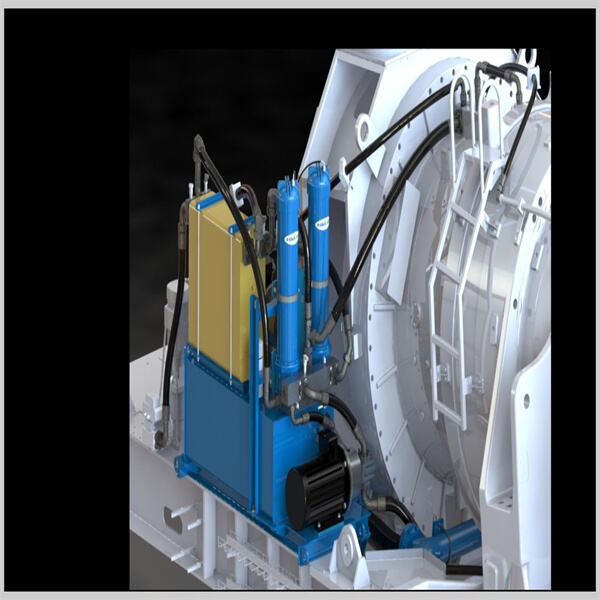

the reason alpha lubrication system has been so designed, and will aptly provide lean oil to your machines, identical to fresh water cooling system by NanJing Fourall. This lubrication practice is called precision lubing. Precision lubrication Like your machine, you probably need the right amount of oil scattered at it — not too much lube but in clear opposition: Not enough. And well-lubricated machines operate with higher efficiency. Low energy consumption and low cost per used bit for companies in their electricity bills.

Alpha lubrication system however can also be useful in making them last longer, the same as NanJing Fourall's fin heatsink. Less friction means less wear and tear on equipment. This kind of damages arises due to wear and tear because the parts begin rubbing against one another when it goes on running. The alpha lubrication system likewise acts to oil or grease these relocating components, which placing an acne breakouts protective shore all around them that assists reduce and tear. This in a way is like putting up a wall to prevent the machine from wearing down so easily and with wear reduction, that means less repairs along the line which will save company even more money later on.

No Machine Truly Runs Gently: Everything from a large piece of pipe, to a tiny valve all the way down to digital flow metering equipment must be appropriately maintained in order for us get solid performance out each machine; at times, this can leave some items unavailable while they are taken offline, just like the thermostat cooling system innovated by NanJing Fourall. The time you have to wait is called downtime and the company loses a lot of money because of it. Supporting this, the grinder comes with an alpha lubrication system that reduces considerably on wait-time making it less labour intensive to keep up. The system also monitors how much of a lubricant is being dispensed into the machine, and does this with automatic sensors. The sensors on their side monitor the machinery to report when extra lubricant is required. Sufficient quantity of lubricant is added automatically by the system. Consequently, this saves workers time from constantly checking lubricant levels while working and helps reduce occurrences of human error during maintenance.

In some types of machines, routine operations are performed under significantly harsh conditions (at high temperature, wetness and etc.). This in turn, will prevent the smooth and efficient working of machines. However, the alpha acutuation system is designed to help in these conditions, similar to the NanJing Fourall's product like radiator cooling system. The system works by employing special lubricants purpose-made to withstand high temperature and are also water-repellent. It is proof that machines, even in the arms of perilous environments can muster and do their job.

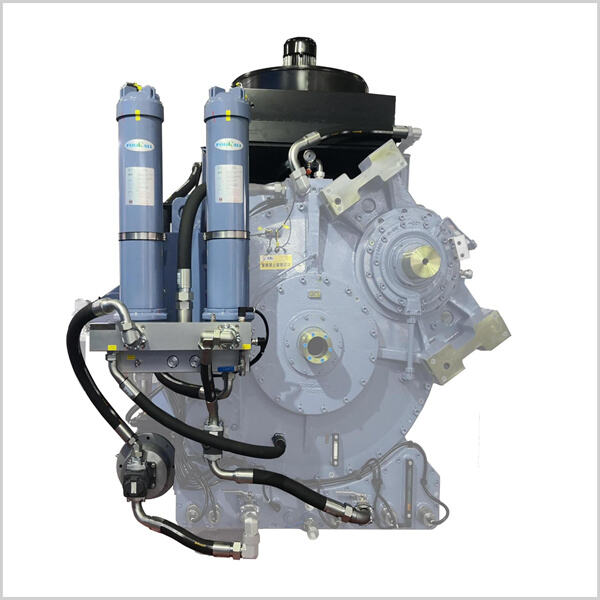

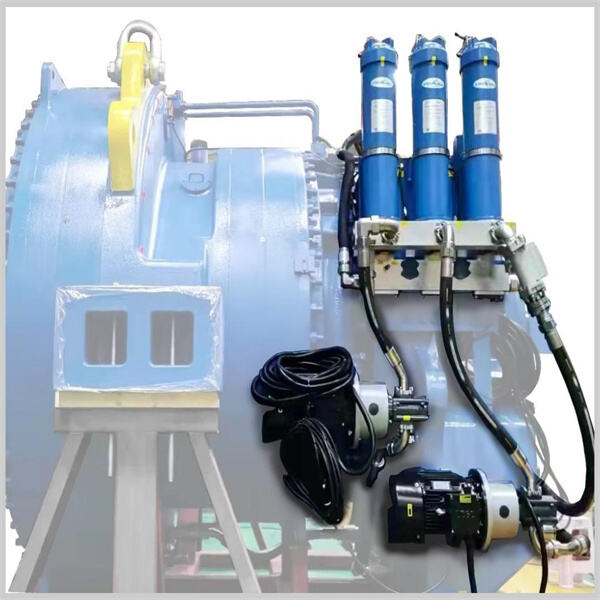

Fourall company has identified two types of products: lubrication as well as water cooling. The company also has a hydraulic products for Alpha lubrication system Water cooling system designed for industrial and large power application. Wind power products have created five series that include more than 40 specifications, including the Wind Power Lubrication series, water-cooled OS series and FA/HC filter element series, patented products pressure follow-up temperature control valve FA/D series and the off-line filtering FA/HU series. We strictly operates the standardized management system of SO9001/14001/18001, standards and procedures that enable us to implement a complete information management and a vertical after-sales service system in the entire chain from RD marketing, RD, manufacturing, supply chain, and quality management. We can quickly meet the demands of customers as well as provide fast and efficient service. The company has offices located in Nanjing and Tianjin in addition to having a an experienced team of sales, tech and service personnel who can provide customers with prompt as well as professional products and technical support.

We've supplied lubrication equipment with a capacity of over 6 000 MW and more than 3000 water cooling units We also have served more than 1 000 wind farms and over 300 wind turbine makers Have formed a win-win collaboration with several renowned domestic main component manufacturers including CSSC Alpha lubrication system DHHI etc Just delivered water cooling system for Dongfang Electric's Wind Power Group's offshore 10MW project in Danzhou Accepted by March 2024 and delivered by April 60 systems will be in place by July Our advanced patented heat dissipation technology wind tunnel lab enabled this feat This achievement highlights Fourall's leading position in offshore water cooling technology and innovation We are committed to constant improvement and commitment to providing top-quality products and services to support the global development of renewable energy

Fourall is a fluid technology company that specialises in the development of products and services employed by various industries, including photovoltaic, wind power, transformer and power transmission stations, building materials and petrochemicals. We develop customized lubrication solutions as well as cooling systems, hydraulic systems components, and cylinders for large-scale equipment. We can provide professional technical support and services to various industries. Our products are built with high standards of craftsmanship and quality control.Our technology has been used successfully in the Photovoltaic power cooling system; Alpha lubrication system hydraulic system Substation SVC converter cooling system cooling system for SVG converters in substations. Industry of petrochemical and metallurgical. Lubricating stations for cooling and oil; Building Material Industry Lubrication station and hydraulic system, as well as cooling process, etc.

Fourall is a group dedicated to the research, development, and manufacture of fluids for large-scale power electronic applications. Our product line includes air-cooling and cooling systems, filter elements mechanical pumps, gear pumps, pipelines for oil, pressure-following TCV filters, off-line bypass, and more.Fourall's well-trained RD team, with their extensive backgrounds in industrial fluid applications, and over a decade of experience in Alpha lubrication system fluid product application, is able to quickly pinpoint and offer technological solutions. Based on the advanced testing equipment and quality control processes, high-tech processing technology, rigorous process management and quality control methods, Fourall can ensuring the quality top-performing, highly efficient customized products to global customers.