The first step is to figure out what if anything needs repair. Water pump not functioning? Fans not spinning properly? The next step is breaking the edges indicating that you have figured which of them are broken and needs to be changed. While you cannot get confused on the issue since identifying it correctly allows for buying the correct parts to fix your cooler.

The next thing you must do is to purchase the new parts you want, along with NanJing Fourall's product hydraulic system. Champion cooler parts are available at many home improvement stores, as well as online. Be sure to check the model of your cooler when shopping The information is important so that you purchase the correct parts that will integrate seamlessly with your model.

So next is to replace these parts. Don’t worry. It is easier to do this than you might think. When it comes to replacing most parts on all Champion coolers they are designed for easy replacement, and you do not need much in the way of tools. InstructionsPackaging of the new parts.

Installing a programmable thermostat is another excellent upgrade to consider, same with the liquid cooling system developed by NanJing Fourall. With this, you can program your cooler to switch on and off at varying points of the day so that depending on how hot it is outside for a certain period or if no one will be home all afternoon. For instance, you can schedule it to turn off just as your school or work day ends so that there is nothing using electricity unnecessarily and thereby not only save power but also lower the amount on your monthly utility bill.

Like any Champion cooler part you need, it is essential to choose decent quality parts, the same as NanJing Fourall's filter in hydraulic system. Cheap or poor-quality parts finally result in the working of your cooler being not good; it can also cause troubles that do with cooling down area too. This is why Champion parts are an excellent option. These are built to last and molded specifically for your cooler type.

In order to maintain the proper functioning of your cooler, you will have to associate care and consideration, also the centralized lubrication system made by NanJing Fourall. Regular maintenance is key. Switching out your old worn-out parts for new Champion parts can help make a difference to how efficient and effective you cooler works. Basic maintenance includes regular air filter and water distribution system cleaning.

Regular maintenance

Check all your cooler compartments regularly for damage and wear, making it the most viable option, just like the NanJing Fourall's product called water cooling system in engine. The second dedicated range day at 600 yards was a bit harder on the rifle with three distinct instances of issues caused by parts failure and made worse when you factor in things like wind pushing your round off target. It is best to replace anything that looks broken or worn out before they end up causing real problems. This is a great way to prevent any future issues and ensure that your cooler works quickly.

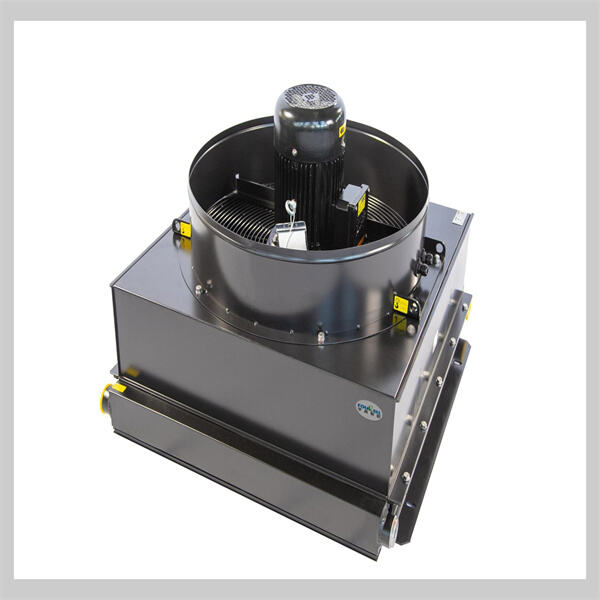

Fourall Company has classified the products into two categories: lubrication, Champion cooler parts, and hydraulic product for wind power applications. Water cooling system for large-scale power and industrial applications. Within them, wind power items have created five series that include more than 40 specifications, including wind power Lubrication WD series, water-cooled OS series and the FA/HC filter element series, patented products pressure following temperature control valve FA/D series, and the off-line filtering FA/HU series. We are a part of the standard management system SO9001/14001/18001 and other standards to provide an extensive information system as well as an integrated after-sales service system. This includes RD, Marketing, Manufacturing, Supply Chain and Quality Management and we are able to respond rapidly to the requirements of our customers. We can also provide quick and efficient service. The company's offices are in Nanjing and Tianjin, and also has a team of professional sales, technology and support staff to provide customers with timely and expert technical and product services.

Fourall team specializes in fluid technology and the products that are widely utilized in wind power generation, photovoltaic power generation, power transmission and transformation stations, metallurgy, construction materials and petrochemical industries. We create custom-designed lubrication systems and cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We offer professional technical support and services for different industries, and we have high quality standards of craftsmanship and management.Our technology is successfully used in Substation SVC Cooling System for Converters. Cooling system for SVG Converters in Substation. Metallurgical petrochemical industry Lubricating stations for cooling and oil; Champion cooler parts and cooling system for hydraulics, equipment, etc.

Fourall team members are committed to the research, development and production of fluid components and fluid products for applications in the field of large-scale and new energy power electronics. Our product range includes Champion cooler parts and air-cooling systems, filters, mechanical pumps, gear pumps pipelines for oil, pressure-following TCVs and bypass filters off-line, etc.Fourall's highly-experienced RD team, with their deep knowledge of industrial fluid applications as well as over a decade of experience in wind energy fluid product application, is able to quickly pinpoint and offer technological solutions. Fourall's advanced processing technology along with the latest testing equipment and quality assurance systems and rigorous quality management systems are built on modern testing and quality assurance systems.

We have supplied lubrication systems that have a capacity of more than 6000 MW, and more than three thousand Champion cooler parts. We have also assisted more than 1, 000 wind farms as well as over 300 wind turbine builders. Have formed a win-win collaboration with several renowned domestic major part manufacturers, such as CSSC, NGC, DHHI, etc. Just delivered water cooling system for Dongfang Electric Wind Energy Group's 10MW offshore project in Danzhou. Accepted by March 2024 and delivered in April, 60 systems will be in place by July. Our advanced, patented heat dissipation technology wind tunnel lab has enabled this feat. This achievement highlights Fourall's leading position in the field of offshore water cooling technology and innovation. We are committed to constant improvement and dedication to providing high-quality solutions and services, assisting global renewable energy development.