If you not aware of what a chiller is, it is an equipment that makes things cold and because a boiler makes them hot these two machines will most likely be close to each other. Both of those machines are very interesting because the NanJing Fourall water cooled chiller system help keep the inside temperatures in buildings, keeping people working or going to school.

In the case of a chiller we are taking fairly warm water from inside the building and cooling it to something like 50-59°F. After the water has cooled off, it is released to be used yet again for other appliances that can perform even more effectively with colder temperatures like air conditioners or fridges. This course of cooling is one such thing that becomes necessary particularly on summer days when those hot and wonderful summers are more chilling.

A boiler, on the other hand, takes cold water and heats it up. And then the hot water is sent to do various things like heat rooms or provide domestic hot-water for taking a bath etc. Hand in hand with a relatively colder winter, is the need to keep our living spaces noticeably warmer than outside – and this heating process that helps us feels warm inside somewhere very important during these times.

If your industrial stitching machine with its high capacity requires cooling measures above beyond what available, another choice is to reply dissipate heat using the chilly water delivered by a chiller. There are a lot of ways to get these machines to effectively collaborate so you can enjoy all the savings possibilities that they bring with NanJing Fourall chilled water ac system.

One simple way to provide relief is by inspecting that your chiller and boiler are functioning side by side. If they are not collaborating in a good way again, wasting this much energy and money is just — I mean it really isn't doing anybody any favors. Better yet, consider an automated control system that will adjust the temperature for you depending on what time of day it is or how many people are in the building. If there are not as many people around, the NanJing Fourall liquid cooling system can then adjust temperature to save power.

Lots of interesting new technologies are being developed to make chillers and boilers work more efficiently while reducing costs. A perfect example of this may be using renewable energy sources, such as solar power or wind electricity assist strength them. This is good for your energy bill AND the planet!

Advanced sensors and controls are other new technologies that work to invoke the temperature more efficiently. These sensors can even determine if a room is too hot or cold and respond within seconds. Not to mention, the materials in use are now more thermally conductive than they have been before and help chillers as well as boilers perform their jobs all the better.

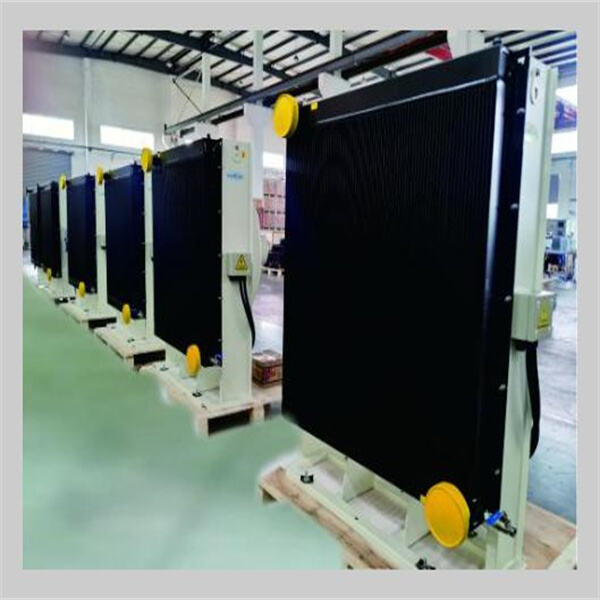

Fourall team is dedicated to research, development and production of fluid-related products and components to be used in the area of renewable energy and large-scale power electronics. Our product range includes air-cooling, oil-cooling, and air-cooling systems. Chiller and boiler system mechanical pumps, gear pumps oil pipes, pressure-following TCV, off-line bypass filters, and many more.With a highly skilled RD team with extensive industrial fluid application backgrounds, and over a decade of experience with wind power fluid product applications, Fourall is capable of efficiently identifying and delivering technological solutions. Fourall's advanced processing technology along with the latest testing equipment and quality assurance methods and quality management systems are built on advanced tests and quality control systems.

Fourall Company has classified the products into two categories: lubrication, Chiller and boiler system, and hydraulic product for wind power applications. Water cooling system for large-scale power and industrial applications. Within them, wind power items have created five series that include more than 40 specifications, including wind power Lubrication WD series, water-cooled OS series and the FA/HC filter element series, patented products pressure following temperature control valve FA/D series, and the off-line filtering FA/HU series. We are a part of the standard management system SO9001/14001/18001 and other standards to provide an extensive information system as well as an integrated after-sales service system. This includes RD, Marketing, Manufacturing, Supply Chain and Quality Management and we are able to respond rapidly to the requirements of our customers. We can also provide quick and efficient service. The company's offices are in Nanjing and Tianjin, and also has a team of professional sales, technology and support staff to provide customers with timely and expert technical and product services.

Fourall team is an expert in fluid technology and the products that are widely utilized in photovoltaic power generation, Chiller and boiler system, metallurgy construction materials and the petrochemical industry. We develop customized lubrication solutions, cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We can provide professional technical assistance and services for various industries. We offer high standards of craftsmanship and quality management.Our technology is used successfully in Substation SVC Converter Cooling System. cooling system for SVG Converter in Substation. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries. Building Material Industry Lubrication system and hydraulic system that includes cooling system.

We have supplied Chiller and boiler system that has a capacity of 6000 MW, and more than 3, 000 water cooling systems. We have also assisted more than 1000 wind farms and more than 300 wind turbine producers. Have established win-win cooperation relationship with a number of renowned main component manufacturers, including CSSC, NGC, DHHI, etc. Just delivered water cooling system for Dongfang Electric's Wind Power Group's 10MW offshore project in Danzhou. In March 2024, the project was accepted and almost 30 sets were delivered towards the end of the month, and 60 systems to be assembled in July 2024. Our innovative, patent-pending performance of heat dissipation in our wind tunnel laboratory was responsible for this feat. This achievement highlights Fourall's leading position in offshore water cooling technology, commitment to innovation, and the commitment to provide high-quality products and services, supporting the global development of renewable energy.