Machines like these need to be well-oiled in order for them to work and actually do the intended jobs. Ever wonder what is all this that oils system in these machines was controlled by us? It’s quite interesting. Control NanJing Fourall lubrication system — What Are They and Why Is It Important? Control lubrication systems are a mechanism, important about control lubricant.

When parts of a machine are lubricated, they move against each other without rubbing. If they rub against one another, pieces may wear down fast and even crack. There are some parts of the machine which required much more oil, and others which don't. Therefore proper control is needed to manage the oil into each part. This is where control lubrication systems have a part to play. These ensure an even amount of oil gets to each piece. If everything has just enough of what it needs, the machine will work well and stay working for a long time without any fixing being needed.

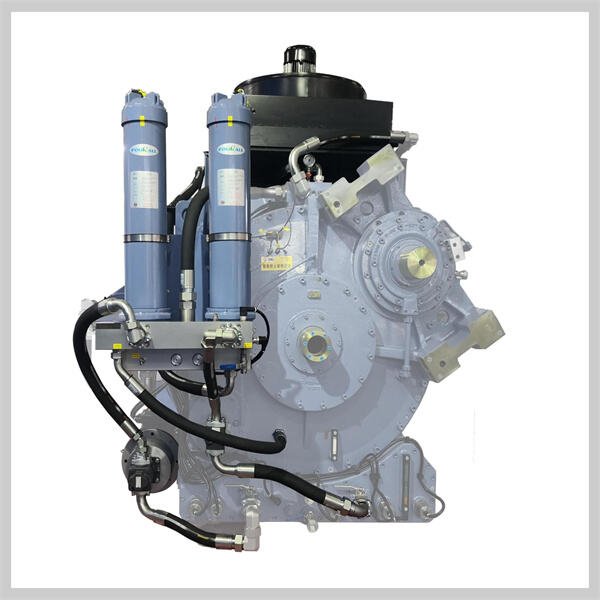

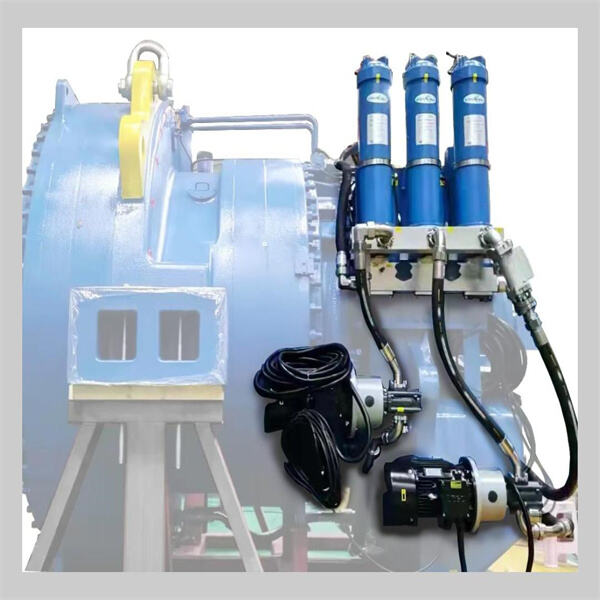

A regulate lubrication system has quite a few parts that each one work collectively. The parts consist of a storage tank for the oil, pumps to move the oil, filters to clean the dirty waste oils again and valves that control flow. Let’s break this down a bit. So, oil tank contains basically the oil which we require for that machine. The pumps are nothing but powerful assistant which pushes forward the oil from the tank into various parts of machine. Cleaning the oil — they clean it as a filter, removing any dirt or impurities in there and this is really important that you have to do because if your oil's dirty for instance or whatever then obviously the machine doesn't work very well. Valves determine how much oil should go to each part, so that every component can get the desired amount. This will enable us to provide each part of the machine with as much oil as it requires for appropriate performance.

One variant is the air-oil lubrication system, which as its name suggests uses air in a loftier role moving oil harmlessly around. NanJing Fourall system lubrication also carries unique control units which help in regulating oil flow to individual parts. Another alternative is to utilize a drip-feed lubrication system; this liquid provides systems gravity controlled flow, they are excellent for small machines that operate at consistent speeds. These are designed as set it and forget, meaning they require little to no minimal maintenance whatsoever.

What makes the Control Lubrication Systems more interesting? They make the machines more efficient to work and decrease abrasion in parts. If everything get the right oil each part can perform it´s job without overheating. This is significant as an overheating machine could easily be destroyed.

They also help to save oil, which means less money is spent buying and storing it. Less oil is also left to discard, as machines have used so little. This is better for the environment and also helps companies save money. In a busy environment another strong advantage of the control lubrication systems is that they can reduce machine downtime due to oil changes and repairs.

Control lubrication system likewise, is quickly evaluated as well as the quantity of oil streaming will soon be readjusted whenever necessary. So you can have everything running its best. In addition, these NanJing Fourall system of lubrication systems do not require much maintenance as they are built to last long and perform without the need for too many adjustments.

We have successfully supplied lubrication systems with an overall capacity of Control lubrication systems, and more than 3, 000 sets water cooling systems, and have supplied over 1000 wind farms. We have also served more than 300 owners of wind farms and wind turbine makers. We have developed a win-win relationship with many famous domestic producers of main components, including CSSC, NGC and DHHI. Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project in Danzhou, Hainan. Accepted in March 2024, over 30 sets were shipped by month's end, with 60 systems to be assembled by July 2024. Our innovative, patent-pending heat dissipation technology wind tunnel lab has enabled this achievement. This achievement shows Fourall's dedication to innovation and dedication to providing services and products of top quality, and aiding global developments in renewable energy.

Fourall team is an expert in fluid technology and the products that are widely utilized in photovoltaic power generation, Control lubrication systems, metallurgy construction materials and the petrochemical industry. We develop customized lubrication solutions, cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We can provide professional technical assistance and services for various industries. We offer high standards of craftsmanship and quality management.Our technology is used successfully in Substation SVC Converter Cooling System. cooling system for SVG Converter in Substation. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries. Building Material Industry Lubrication system and hydraulic system that includes cooling system.

Fourall team is dedicated to research, development and production of fluid-related products and components to be used in the area of renewable energy and large-scale power electronics. Our product range includes air-cooling, oil-cooling, and air-cooling systems. Control lubrication systems mechanical pumps, gear pumps oil pipes, pressure-following TCV, off-line bypass filters, and many more.With a highly skilled RD team with extensive industrial fluid application backgrounds, and over a decade of experience with wind power fluid product applications, Fourall is capable of efficiently identifying and delivering technological solutions. Fourall's advanced processing technology along with the latest testing equipment and quality assurance methods and quality management systems are built on advanced tests and quality control systems.

Fourall Company has classified products into two categories namely water cooling, lubrication and hydraulic product for wind power applications. Water cooling system for large industrial and power applications. Within them, wind power items have created five series that include more than 40 specification, including wind power Lubrication WD series, water-cooled Control lubrication systems and FA/HC series of filter elements, patent-pending products for pressure following temperature control valve FA/D series and off-line filtering FA/HU series. We adhere to the SO9001/14001/18001 standard management system and the standards that provide a comprehensive information system and a vertical after-sales system. This includes RD Marketing, RD Supply Chain, Manufacturing, Quality Management, and we're able to respond rapidly to the requirements of our clients. We also offer fast and efficient service. The business has offices in Nanjing, Tianjin and Chengdu equipped with the latest sales, technology, and service teams to offer customers timely and high-quality products and services.