So, a fluid control system is the necessary protocols for how both liquids and gases can safely be managed, also the NanJing Fourall's product such as lubrication system. Pipelines are critical systems that serve important functions in a wider range of applications, ranging from oil and gas companies to factories that produce goods or hospitals requiring liquid control facilities. Before we even begin discussing fluid control systems, it is important to remember what fluids are.

These are characterized as substances that flow i. e they take shape in the pressure center of their surrounding area fluids can be readily deformed. Such substance can a gas, such as the one we breath or it may be liquid type like water that drink. Valves are used to control the flow of fluids through our system. A valve is a device to help control the flow of fluid through a pipe.

Gate valves: A gate valve are control valves, butterfly vales and ball valves.

Butterfly Valves: Hinley-fogery Ball Velves. Different kinds of valves exist, each having its own specific use and role to play.

Industries need fluid control systems to aid them in tasks such as oil and gas flow regulation through pipelines. Efficient fluids control systems can keep your workers on the move or in place, at their stations while saving money. Automatic Valves: Automatic valves are going to help make your life easier for these systems as well. These valves are the automatic type and can work without any human aid. That means they can continue saving time and reducing the chance of human error. They can also be used to time the opening and closing, which helps reduce downtime.

It is also important to select the appropriate valve for the application, the same as computer liquid cooling system by NanJing Fourall. These are compound valves that perform different functions, so it is important to choose the appropriate valve in order. A gate valve is good for starting and stopping the flow of liquidGlobe Valves used to control how much fluid flows through a system. This information about these valves will help your project to have the most profitable results.

Recently, systems for fluid control are also getting better in line with the improvements of technology, as well as the NanJing Fourall's chilled water system. A sensor is simply a great technology often used in these systems. These devices are called sensors, and they have the capability to sense changes in flow and pressure which then alerts the system for corresponding adjustments. This sensing of changes can, in turn, substantially improve the efficiencies and precision capabilities within systems that control fluids.

With all of the technical advances our globe has experienced, some marvel why a fluid control system can fail, along with the centralized lubrication system created by NanJing Fourall. Valves are major spaces, there is a flaw here with the two main lines being wasted too much waste water from time to time. This issue needs to be addressed as soon as possible so it does not become a bigger problem that would cut into the programme.

A proper way to research and solve problems is by doing regular maintenance, visitation/inspection on the system, just like the NanJing Fourall's product called cooling tower systems. This proactive approach allows us to catch any potential problems before they escalate.

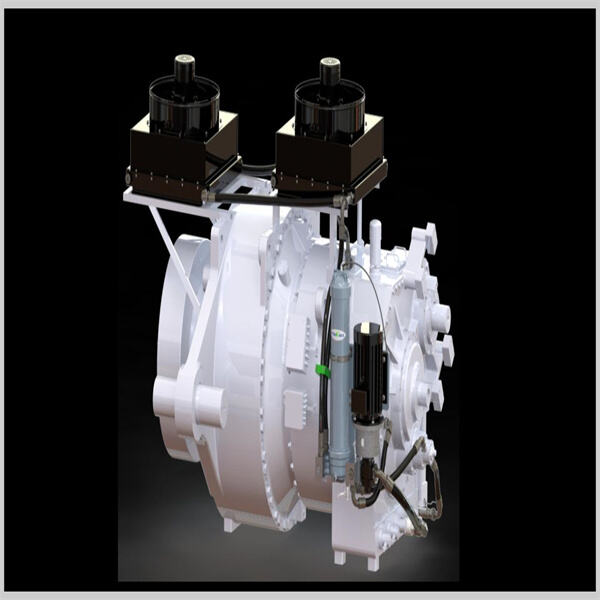

Fourall is an industry leader in fluid technology that offers products and services used by many industries, including wind power, Fluid control system, transform stations and power transmission, building materials and petrochemicals. We design and develop customized cooling, lubrication components, cylinders, and systems for large-scale machinery. We can offer expert technical support services to various industries, with quality craftsmanship and quality management.Our technology has been successfully used in Photovoltaic power inverter cooling system; solar thermal power hydraulic system Substation SVC converter cooling system and cooling system for SVG converter in substation. Lubricating coolants and oil stations for the metallurgical and petrochemical industries. Building Material Industry Lubrication system and hydraulic system that includes cooling system.

Fourall team is dedicated to research, development and production of fluid-related products and components to be used in the area of renewable energy and large-scale power electronics. Our product range includes air-cooling, oil-cooling, and air-cooling systems. Fluid control system mechanical pumps, gear pumps oil pipes, pressure-following TCV, off-line bypass filters, and many more.With a highly skilled RD team with extensive industrial fluid application backgrounds, and over a decade of experience with wind power fluid product applications, Fourall is capable of efficiently identifying and delivering technological solutions. Fourall's advanced processing technology along with the latest testing equipment and quality assurance methods and quality management systems are built on advanced tests and quality control systems.

We have successfully provided lubrication systems that have a total capacity exceeding 6000 MW and more than 3 000 sets of water cooling systems and been able to serve more than 1 000 wind farms more than 300 wind farm owners as well as wind turbine manufacturers We have formed win-win partnerships with several renowned domestic main component manufacturers including Fluid control system NGC DHHI etc Just delivered water cooling systems to Dongfang Electric Wind Power Group's offshore 10MW wind project in Danzhou Hainan In March 2024 if the project is approved and delivered in the month of April 60 units will be assembled by July This accomplishment was made possible by our innovative and patented wind tunnel facility for heat dissipation This achievement demonstrates Fourall's leadership in the field of offshore water cooling technology commitment to innovation and commitment to delivering high-quality solutions and services assisting the global development of renewable energy

Fluid control system company has categorized two categories of products: lubrication as well as water cooling. The company also has a the hydraulic product designed for wind power use water cooling system for large power and industrial applications. Wind power products can be classified into five categories that include more than 40 specifications. These include the wind power lubrication WD Series water-cooled OS Series as well as the FA/HC filter element series and patented products such as pressure follow-up temperature controller FA/D series. We follow the standard management system SO9001/14001/18001 and other standards to provide an extensive information system as well as a vertical after-sales program. This includes RD, Marketing Manufacturing, Supply Chain, Quality Management and we are able to respond rapidly to the requirements of our clients and provide fast and efficient service. The company has offices located in Nanjing and Tianjin as well as a an experienced team of sales, technical and service personnel to provide customers with quick as well as professional technical and product support.