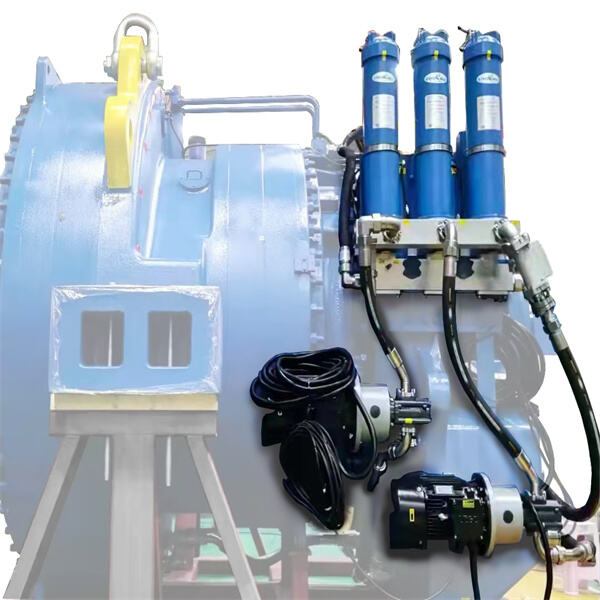

We see hydraulic systems play a very important role in many machines around us everyday. These are systems that enable us to do a lot of work such as moving heavy objects, digging deep holes or the displacement and placement of major instruments etc. Sir, many activities would last longer and be harder to accomplish without hydraulic systems. The hydraulic pump is an essential component of these hydraulic systems. It transforms mechanical power into hydraulic force to perform the equipment. Gear Drive Hydraulic Pumps Primarily known for its strength and efficiency, the Gear Drive hydraulic pump is one of this model.

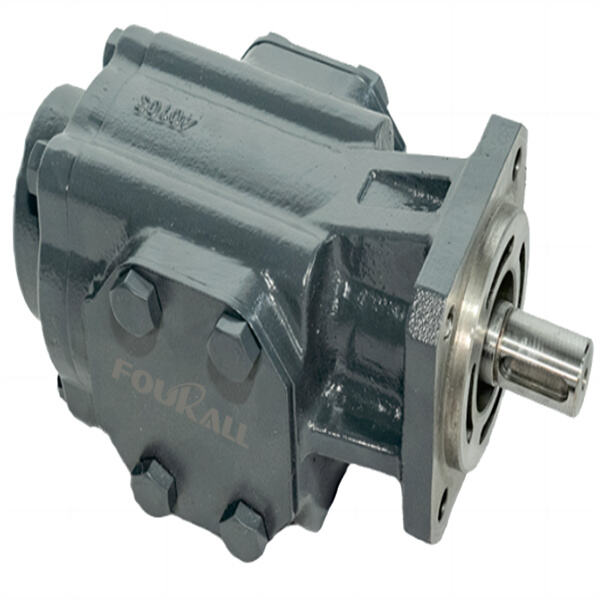

Gear drive hydraulic pumps are unique since they use two gears which operate together to create suction and pressure. As they turn, the gears create a suction effect that draws fluid into the pump. This is important as the pump requires fluid to operate effectively. After the fluid enters into the pump, gears gear up and relocates liquid under stress. That pressure is very helpful because it powers the different sections of a hydraulic system like the hydraulic cylinders, and motors which are needed for achieving specific tasks with that machine.

Gear drive hydraulic pumps are known for their efficient performance, which is one of the biggest pluses while operating with thesesemblies. Because of their simplistic design they can move a lot of fluid without having to use high pressure. This can be particularly helpful for anybody who is aiming to have maximum efficiency, and simultaneously minimal sound levels. This makes a world of difference for workers, such as those on the construction site or in factories.

Durability is another element of gearbox lubrication systems that stand out. They also have a lower number of moving roughly parts than any other pump type. Which means they should be both more reliable and less prone to breakdowns, so they make a solid choice for many applications. As you are in the middle of a project, servicing is not something that will keep your pump running when and where it needs to. This means that they will be a reliable option for any job where you cannot afford to have one go down.

Gear Drive Hydraulic Pumps As Well Enhances The Performance Of Entire Quality System : The reason is they can maintain constant pressure and flow rates, which even the resistance increases. This keeps gear pumps used in hydraulic systems running at the same speed and power level no matter how much or little load is being carried. Whether the machine is lifting something very heavy or just elevator parts transporting something light, gear pumps are equipped to make sure it all goes smoothly.

So, if you are considering avenues to improve on your hydraulic system use our gear drive hydraulic pumps. The carefully thought out design of our pumps makes them both efficient and reliable whilst also providing high performance The potential uses are numerous including construction, manufacturing and agriculture. Our gear pumps are a powerful solution for solid hydraulic tasks,.