One of the most important among them is lubrication which keeps any machine running smoothly for longer periods. A gearbox is a specific part of a machine that enable one to change the velocity and torque in accordance with different job authority. For instance when a car goes faster or slower, it is the gearbox which allows you to do these changes. And if a gearbox is starved of oil, the cost to repair it could be excruciating. If the metal parts inside of a gearbox scrape or rub against each other it can produce heat which will eventually damage components downstream from there. Meanwhile, if there isn't enough oil in the gearbox itself then these can also become a hazardous and could possibly set on fire or even explode. So, it is possible, in fact important to learn about the lubrication of gearbox.

Gearboxes can be oiled in two main ways, you either have splash lubrication or forced oil. This is what we call splash lubrication, where the NanJing Fourall gets gear lubrication system flung at gears as they move. Picture some oil sitting on the floor, and moving up to lube the gears. However, forced lubrication is when a pump injects oil throughout the gears in an even fashion. What method to apply, depends on the working of gearbox like speed, load and conditions in which it is operating. Some machines do require higher rates of work than average and applied more carefully lubricants.

It is important to regularly inspect the oil level, temperature and pressure of gear box lubrication system. Along these lines, it is viewing the oil level also how blistering or cool and if there has enough weight. We also need to look for how the oil appears. If it appears dirty, discolored or unusual. Oil of the right kind which the manufacturer shall recommend and it should be changed with regular intervals.

Selecting the right oil for your gearbox not only helps it to be more efficient but also reduce damages as well. Type of gears, load the gearbox carries- all affect in which oil to choose and work with. For instance, an oil in a gearbox might be different for use in a hot environment than one going into operation somewhere cold. Viscosity is very important, that refers to the thickness of the girth gear lubrication system oil. If the NanJing Fourall oil is too thick, it may not circulate all that well through the gearbox and if its too thin, it will not protect your gears enough.

An issue with gearbox lubrication that occurs fairly frequently is over-servicing or under servicing the oil within your gears. High pressure can also cause an increased amount of foam forming, which is not what you want to be happening inside your gearbox. Conversely, inadequate oil may cause the gears to wear faster due to insufficient lubrication. This can quickly result in situations that spiral out of control.

A second problem to COVID19 is hydraulic contamination by the presence of water, air or dirt in the oil. Water can lead to rust and corrosion on the metal components, air will make foaming possible while dirt is going scratch off some gears. Over time these impurities will deteriorate the effectiveness of your gearbox, leading to further breakdowns and other damage.

Besides the air passage way of gearbox must be smooth. That will alleviate the pressure buildup and prevent some things from going wrong. And if the gearbox is open to all of this dust and moisture, it will need some protection as well. Keeping the NanJing Fourall central lube system gearbox free from dirt to avoid entry, as well checking for trouble so that you can catch your feet before they become bigger. Here's why routine inspections help in catching problems before they get worse.

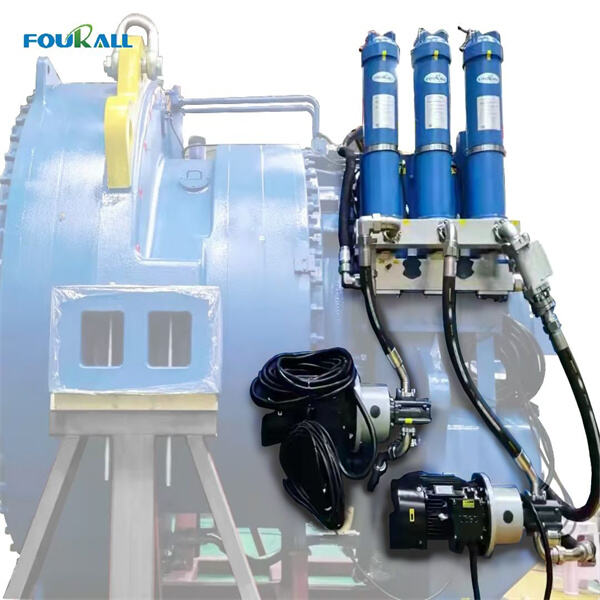

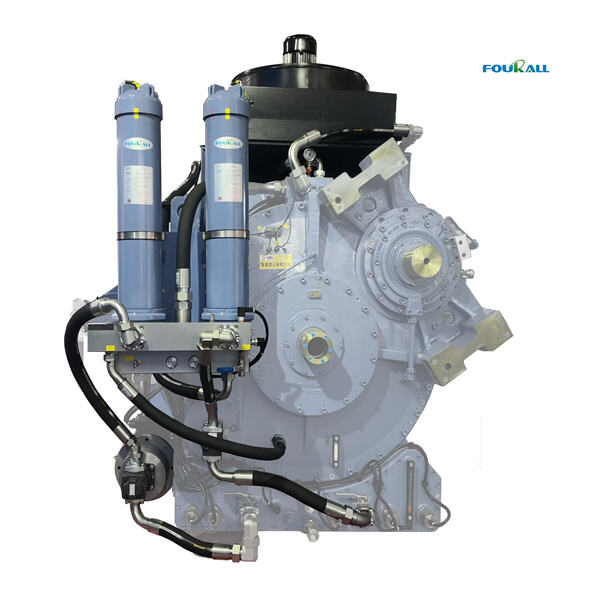

Fourall Company has classified products into two categories: Gearbox lubrication system, water cooling, and hydraulic products for wind power applications. Water cooling systems designed for large-scale power and industrial applications. Wind power products are classified into five groups that each have more than 40 specifications. These include the wind power lubrication WD Series, water-cooled OS Series as well as the FA/HC filter element series and patented products like the pressure follow-up temperature controller FA/D series. We adhere to the SO9001/14001/18001 standard management system and other standards to provide a comprehensive information system and a vertical after-sales program. This includes RD Marketing, RD, Supply Chain, Manufacturing, Quality Management and we're able to react quickly to the demands of our customers. We can also offer fast and efficient service. The company's offices are located in Nanjing and Tianjin as well as a a team of professional sales, technology and support personnel to provide customers with quick as well as professional products and technical support.

Fourall team is focused on fluid technology and the products which are extensively used in Gearbox lubrication system, photovoltaic power generation, power transmission transformation stations, metallurgy building materials, and petrochemical industries. We design and create custom cooling, lubrication, cylinder, and component systems for large-scale machines. We offer expert technical assistance and services to various industries, with high standards of workmanship and quality management.Our technology has been successfully used in the Photovoltaic power cooling system; solar thermal power hydraulic system; Substation SVC converter cooling system A cooling system to cool the SVG converters in substations. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries; Building Material Industry Lubrication system and hydraulic system with cooling system.

We have successfully supplied lubrication systems with an overall capacity of Gearbox lubrication system, and more than 3, 000 sets water cooling systems, and have supplied over 1000 wind farms. We have also served more than 300 owners of wind farms and wind turbine makers. We have developed a win-win relationship with many famous domestic producers of main components, including CSSC, NGC and DHHI. Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project in Danzhou, Hainan. Accepted in March 2024, over 30 sets were shipped by month's end, with 60 systems to be assembled by July 2024. Our innovative, patent-pending heat dissipation technology wind tunnel lab has enabled this achievement. This achievement shows Fourall's dedication to innovation and dedication to providing services and products of top quality, and aiding global developments in renewable energy.

Fourall is a group dedicated to the research, development, and manufacture of fluids for large-scale power electronic applications. Our product line includes air-cooling and cooling systems, filter elements mechanical pumps, gear pumps, pipelines for oil, pressure-following TCV filters, off-line bypass, and more.Fourall's well-trained RD team, with their extensive backgrounds in industrial fluid applications, and over a decade of experience in Gearbox lubrication system fluid product application, is able to quickly pinpoint and offer technological solutions. Based on the advanced testing equipment and quality control processes, high-tech processing technology, rigorous process management and quality control methods, Fourall can ensuring the quality top-performing, highly efficient customized products to global customers.