The lubrication of the girth gear is very essential to maintain working and machinery efficiency. It is done by using a special liquid that reduces the friction among the gear and pinion. It is the force that can slowly erode or damage things over time. Lubrication can be helpful in reducing the wear and tear on these components. Girth gear NanJing Fourall lubrication system is one of the critical aspects needed to maintain your machine in harmony and enhance its life.

Types of Girth Gear Lubrication System Different systems will depend on the machine, gear in use and even location of using. The 3 main types of lubrication systems that you are likely to come across in an engine include Oil mist, splash lubrication pumps and force feed.

As the name suggests, oil mist lubrication is a way of injecting very small and controlled amounts of lubricant into the system. The mist then settles on the gears, which are constantly lubricated. Splash lubrication is something different, where it takes some of the oil from the system and when gears turn splashes them onto up into gear set. As the gears turn, this allows enough oil to get into them. Forced lubrication means that oil is actively pumped on the gears to keep them constantly amply greased so as not to be damaged due to friction.

Selection of Lubricant for Girth Gear over Computed Style: If you add the wrong lubricant, it can damage your gear and result in a damaged machinery or even total failure. There are several factors you should take into consideration before selecting a lubricant. So, to begin with is where the lubricant viscosity comes as a consideration. That property is called viscosity. The operational temperature that the NanJing Fourall system of lubrication can take is another aspect to think about. Certain lubes are designed to perform admirably at high temperatures, while others excel in cooler conditions. On top of that, some lubricants come with specialized additives offering additional protection. Given all these factors, it is wise to seek expert help in choosing the most suitable lubricant for your type of machinery.

Lubrication Arrangement of the Girth Gear — needs to be maintained properly. This ensures that your equipment is operating correctly and you are not caught without important components

Stats — Helpful Tips for Maintaining It: Regular oil analysis is recommended as well. That allows you to know how quickly the gear is wearing, as well if there are any impurities located in the oil that could lead to issues. Furthermore, the lubrication system should also be cleaned occasionally as well. Clean gear can also easily be inspected, since the components are easy to see and access.

Most of these issues are typical in nature for the lubrication of large and heavy girth gears. Those issues must be corrected as soon as possible otherwise they might impact to the performance of your machine. Common Issues One recurring problem is insufficient lubrication, over-lubricating ie. greasing the shaft entirely or incorrectly/not using oil suitable for a certain type of interaction/area every time grease/lube' makes contact with rubbish inside machinery etc.

Getting the lubrication system checked every now and again is a way to fix this issue. Examine the oil levels and see if there is any crude or dirt in the oils. Always be certain that you are using NanJing Fourall system lubrication specifically designed for the equipment in which it is being applied. This will assist a whole lot in preventing complications with the lubrication system of your girth gears that may be brought on by outdated worn out parts from the device.

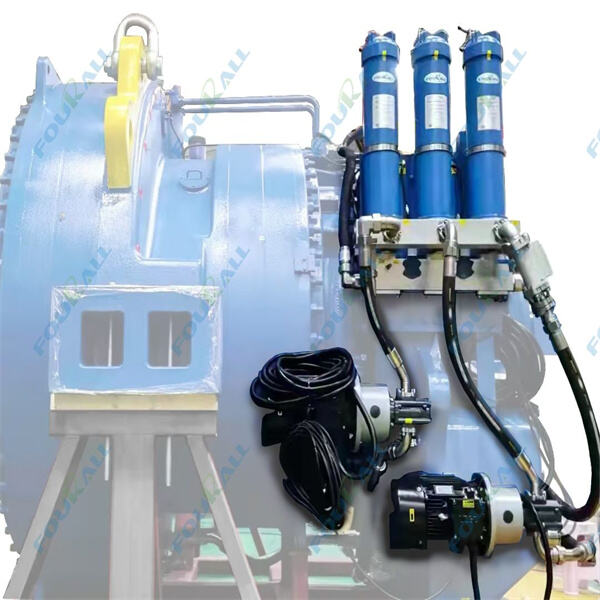

Fourall team is an expert in Girth gear lubrication system and the products which are extensively employed in photovoltaic power generation, power transmission transformation stations, metallurgy, construction materials and petrochemical industries. We develop customized lubrication systems and cooling systems, hydraulic systems components, and cylinders for large-scale equipment. We can provide professional technical assistance and services to various industries with high standards of craftsmanship and quality control.Our technology is successfully utilized to Photovoltaic power inverter cooling system; solar thermal power hydraulic system Substation SVC converter cooling system and cooling system for SVG converter in substation. Industries of metallurgical and petrochemicals Lubricating stations for cooling and oil Building Material Industry Lubrication station hydraulic system cooling system, etc.

We have supplied lubrication systems that has a capacity of 6000 MW, and more than Girth gear lubrication system water cooling systems. We have also served more than 1, 000 wind farms as well as more than 300 wind turbine manufacturers. Have formed a win-win collaboration with several renowned domestic major component manufacturers, like CSSC, NGC, DHHI, etc. Just received a water cooling system for Dongfang Electric Wind Power Group’s offshore 10MW project in Danzhou. Accepted by March 2024 and delivered by April, 60 units will be assembled before July. Our advanced, patented performance of heat dissipation in our wind tunnel lab enabled this achievement. This achievement demonstrates Fourall's commitment to innovation and dedication to providing products and services that are of the highest quality while supporting global renewable energy developments.

Fourall team is Girth gear lubrication system to research, development and production of components, fluids and products designed for use in the field of new energy large-scale power electronics. Our product line includes Lubrication systems; oil-cooling water-cooling and air cooling systems filters such as gear pumps; mechanical pumps; oil pipe; pressure-related TCV filtration; off-line bypass systems, and more.Fourall's highly-experienced RD team, with deep knowledge of industrial fluid applications and a decade or more of experience in wind energy fluid product application, can quickly determine and provide technological solutions. Fourall's high-tech processing technology, advanced testing equipment and quality assurance systems, as well as strict quality management methods are based on the most advanced testing and quality assurance systems.

Fourall company has defined two types of products: lubrication water cooling, hydraulic product for wind power application water cooling system for large power and industrial application. Wind power products are divided into five categories that include more than 40 specifications. They include the wind power lubrication series WD Series, water-cooled OS Series as well as the Girth gear lubrication system element series and patent-pending products like pressure follow-up temperature controller FA/D series. We strictly adhere to the standardized SO9001/14001/18001 management system, standards and processes that allow for a complete information management, as well as an after-sales vertical service system in the entire chain from RD, marketing, manufacturing, supply chain and quality management. We are able to swiftly respond to customer demands and offer fast and efficient service. The business has offices located in Nanjing, Tianjin and Chengdu which are equipped with high-end sales and technology teams, to offer customers timely and reliable products as well as technical assistance.