With the help of hydraulic systems, many machines and things that work with force to move. Fluids, such as either oil or water liquid the systems to aid in proper and easy movements. NanJing Fourall hydraulic system worldwide are unique as they can utilize by anyone across all regions of the world. They make machines and other tools work great. These systems have great attributes that make them very useful within a range of industries and applications.

Hydraulic systems are the tools that use fluids to run, capable of doing multiple operations. The common liquids would be oil or water which is pumped into a cylinder that houses an internal piston. The piston is very important because it moves when the liquid to be pumped in. As the fluid is pumped in on one side of cylinder, it moves a piston to other side. This motion generates huge power that can be used for lifting heavy items, moving things or even crushing materials also. That power is what makes hydraulic systems so sought-after in just about all fields of study.

Machines can do work for people instead but it is significantly lower in importance. Machines do jobs that may be tough, or even dangerous for human beings to deal with. Specialized NanJing Fourall main components of hydraulic system can push the machinery to work in a superior fashion both globally. These systems are responsible for maintaining and controlling the machinery to perform their tasks properly, doing what they ought to do. They are also able to monitor the machines to keep them secure and properly running. The production is monitored for a few seconds which prevents any accidents and keeps everything in place, so that the work setting becomes safer to avoid damage.

The Hydraulic systems are used around the world and offer plenty of benefits which make them ideal for diverse applications. First, they are very strong. They can power machines to lift heavy things or crush big rocks with unmatched ease. They are also very precise. This makes them excellent at controlling machines, which is key if you need something to be very precise -- like in surgery or creating tiny computer parts. These areas require precision to ensure that no endangering mistakes are made. Additionally, the hydraulic systems are globally very durable and last for many years without breaking down or needing to be repaired.

Having safety and accuracy is incredibly crucial in dealing with international hydraulic systems. NanJing Fourall electric hydraulic system are incredibly fast systems and can be lethal if not executed properly. As such, it is absolutely necessary that those who work with these systems be appropriately trained. They have to experience how the machine being operated and another growth is. Training makes the right level of risk and how to prevent such accidents understandable for everyone. The Global hydraulic systems can also help machines be controlled really effectively. In another aspect of fine control, drones and a number of other robot types have high precision or resolution. They can do things with 1/10th mm accuracy level — an element crucial to fields such as surgery where the difference in millimeters is likely saving lives.

This is one of the most important points to see that why machines are required to be less polluted. Machines can produce by-products that are bad for the environment and people. This is a crucial waste to manage and taking care of these globally with hydraulics systems will significantly lower this pollution. They are quite energy efficient, which means they consume low power for the same amount of work as other systems. This not only saves energy, but also looks environmentally friendly. Furthermore, these systems do not breakdown often, and since they are reliable you will reduce even more waste land pollution.

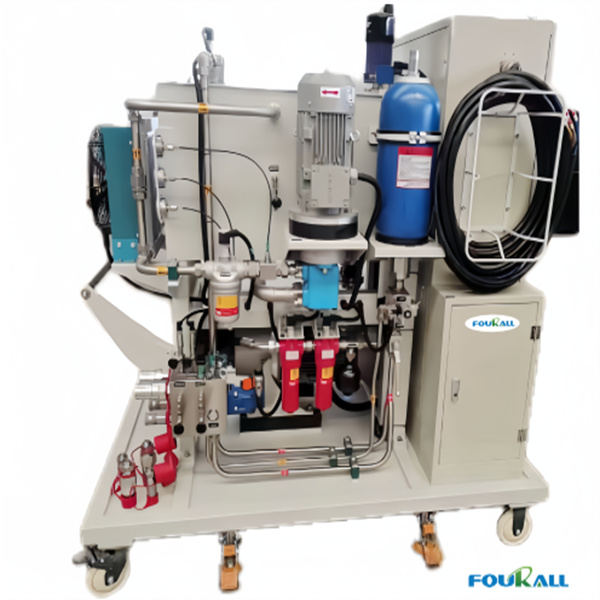

Global hydraulic systems team members are committed to the development, research and production of fluid components and fluid products that are used in the field of energy innovation and large-scale power electronics. Our product line includes oil-cooling and air-cooling systems, filter elements mechanical pumps, gear pumps oil pipes, pressure-following TCV filters, off-line bypass, etc.With a highly experienced RD team that has an extensive background in industrial fluids, and over a decade of expertise in wind power fluid application, Fourall is capable of quickly identifying and providing technological solutions. Fourall's high-tech processing technology with advanced testing equipment, quality assurance systems and rigorous quality management systems are built on advanced tests and quality control systems.

Global hydraulic systems company has categorized two categories of products: lubrication as well as water cooling. The company also has a the hydraulic product designed for wind power use water cooling system for large power and industrial applications. Wind power products can be classified into five categories that include more than 40 specifications. These include the wind power lubrication WD Series water-cooled OS Series as well as the FA/HC filter element series and patented products such as pressure follow-up temperature controller FA/D series. We follow the standard management system SO9001/14001/18001 and other standards to provide an extensive information system as well as a vertical after-sales program. This includes RD, Marketing Manufacturing, Supply Chain, Quality Management and we are able to respond rapidly to the requirements of our clients and provide fast and efficient service. The company has offices located in Nanjing and Tianjin as well as a an experienced team of sales, technical and service personnel to provide customers with quick as well as professional technical and product support.

Fourall team is focused on fluid technology and the products which are extensively used in Global hydraulic systems, photovoltaic power generation, power transmission transformation stations, metallurgy building materials, and petrochemical industries. We design and create custom cooling, lubrication, cylinder, and component systems for large-scale machines. We offer expert technical assistance and services to various industries, with high standards of workmanship and quality management.Our technology has been successfully used in the Photovoltaic power cooling system; solar thermal power hydraulic system; Substation SVC converter cooling system A cooling system to cool the SVG converters in substations. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries; Building Material Industry Lubrication system and hydraulic system with cooling system.

We have successfully supplied lubrication systems with an overall capacity of 6000 MW and more than 3 000 sets water cooling systems and have provided services to more than 1 000 wind farms We have also served more than 300 owners of wind farms and Global hydraulic systems We have built win-win relationships with several prominent domestic manufacturers of main parts such as CSSC NGC and DHHI Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project located in Danzhou Hainan Accepted by March 2024 and delivered in the month of April 60 systems will be in place before July This accomplishment was made possible through our innovative and patented wind tunnel laboratory for heat dissipation This achievement is a testament to Fourall's commitment towards innovation and dedication to offering products and services of high quality while helping to support global renewable energy development