Hello, friends! In this episode we will be discussing about one of the most crucial systems to machines that is Lubrication. So what are you wondering, “What is Range of lube system”? Well, let’s start there. This is a means to apply oil or grease around the parts of any machine that moves, hence sometimes it may be known as Lube system. Accepted Normal Use, It is supposed to be seamless and trouble free! Like we need water every day for survival and performance, you need the lubrication in order to enjoy what your well-oiled running machine has to offer. Oil acts as a lubricant for the parts of your machine so that they do not grind to each other. This rubbing action generates a friction that causes heat to be created. Overheat might harm the machine and make it less resilient than usual.

Having explained what the Lube system exactly is and why one should use lube systems, let us now have some details on the Industrial type of lube. NanJing Fourall central lube system are often used in large, Adult-Onset working machines and tend to be placed at factories, mines along with other hot work environment. These machines have thousands of moving parts which rely on oil to operate while meeting the correct specifications.

This kind of oiler gives a constant supply at every point so as to eliminate overheating or rust, increase efficiency levels and also reduce maintenance and operating costs. The way it works: Manual lube system is just like you have to come up and put grease in the thing — equivalent a bike chain or anything else equipment. With the lubrication, an automatic lube system is simply a way of getting oil on the machine without doing it all manually. It does so by employing special tubes and nozzles in a position to spray the oil directly on where its components are needed. It ensures that your machine always keep running and dripping oil without human interaction.

A little known secret about it lube system, can do wonders for your machines! One of the more essential methods in which machine learning can help is by doing the repetitive labor for machines. To put it frankly, a well-oiled machine. In turn, this will translate into getting the job done sooner and without any unnecessary waste of energy in the first place. NanJing Fourall centralized lube system, one that completes tasks quickly and efficiently while still leaving you with plenty of time or resources.

Something to remember if you do use a lube system is the fact that this type of oiler can help your machine last longer. NanJing Fourall basic hydraulic system is the process by which a machine greases its moving parts so that they will not rub together and get too hot. All of this heat will mean some components that wear down while others will just break. When you use the right oil in these machines they can help to protect parts that are prone to breakage and prevent catastrophic failure which might happen on its journey. A quality lube system will keep your machine functioning properly, and allow it to function for many years down the road.

If you seek the services of great lube service provider, in which to stay clear that your maintenance routine will be placed for a long period when regular checks can often handled regarding it. Be in the listening mode: Listening to leaks, fill up your oil tank and tubes/nock handles.

Right oil: You should always use the right class of apple ipad to your gear; Honestly speaking this will ruin your machine and also killing it (shorten of the lifespan). Therefore, it is important that you should always follow the lubricants recommended by the manufacturer as per manual.

Operateur training: This is maintenance and should be checked often for appropriate operator/care of lube system. Make sure that they are using, and looking after the lube system in a manner by which it will operate properly.

We have successfully supplied lubrication systems with an overall capacity of 6000 MW and more than 3 000 sets water cooling systems and have provided services to more than 1 000 wind farms We have also served more than 300 owners of wind farms and Lube systems We have built win-win relationships with several prominent domestic manufacturers of main parts such as CSSC NGC and DHHI Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project located in Danzhou Hainan Accepted by March 2024 and delivered in the month of April 60 systems will be in place before July This accomplishment was made possible through our innovative and patented wind tunnel laboratory for heat dissipation This achievement is a testament to Fourall's commitment towards innovation and dedication to offering products and services of high quality while helping to support global renewable energy development

Fourall team is focused on fluid technology and the products which are extensively used in Lube systems, photovoltaic power generation, power transmission transformation stations, metallurgy building materials, and petrochemical industries. We design and create custom cooling, lubrication, cylinder, and component systems for large-scale machines. We offer expert technical assistance and services to various industries, with high standards of workmanship and quality management.Our technology has been successfully used in the Photovoltaic power cooling system; solar thermal power hydraulic system; Substation SVC converter cooling system A cooling system to cool the SVG converters in substations. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries; Building Material Industry Lubrication system and hydraulic system with cooling system.

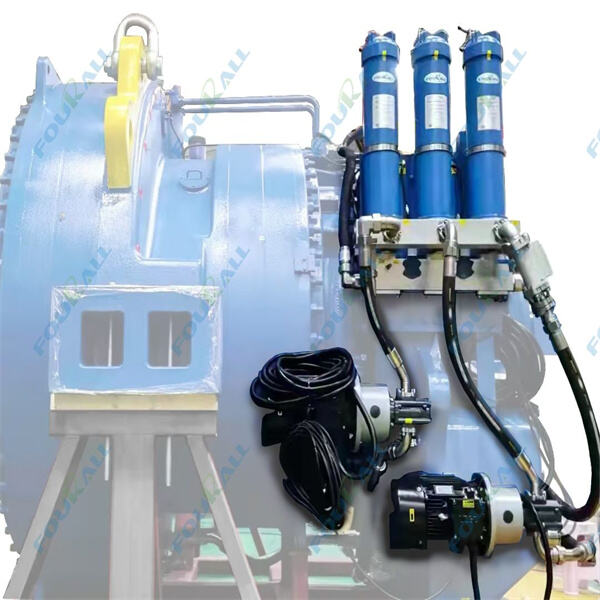

Fourall team is Lube systems to research, development and production of components, fluids and products designed for use in the field of new energy large-scale power electronics. Our product line includes Lubrication systems; oil-cooling water-cooling and air cooling systems filters such as gear pumps; mechanical pumps; oil pipe; pressure-related TCV filtration; off-line bypass systems, and more.Fourall's highly-experienced RD team, with deep knowledge of industrial fluid applications and a decade or more of experience in wind energy fluid product application, can quickly determine and provide technological solutions. Fourall's high-tech processing technology, advanced testing equipment and quality assurance systems, as well as strict quality management methods are based on the most advanced testing and quality assurance systems.

Fourall Company has classified products into two categories: Lube systems, water cooling, and hydraulic products for wind power applications. Water cooling systems designed for large-scale power and industrial applications. Wind power products are classified into five groups that each have more than 40 specifications. These include the wind power lubrication WD Series, water-cooled OS Series as well as the FA/HC filter element series and patented products like the pressure follow-up temperature controller FA/D series. We adhere to the SO9001/14001/18001 standard management system and other standards to provide a comprehensive information system and a vertical after-sales program. This includes RD Marketing, RD, Supply Chain, Manufacturing, Quality Management and we're able to react quickly to the demands of our customers. We can also offer fast and efficient service. The company's offices are located in Nanjing and Tianjin as well as a a team of professional sales, technology and support personnel to provide customers with quick as well as professional products and technical support.