Heat sinks come in the form of a skived heat sink, which is one such instrument designed to cool various electronics like computers, laptops, tablets and cell phones, as well as the NanJing Fourall's basic hydraulic system. This is because a cooling instrument that helps to prevent the devices from heating and thus does not affect or spoil any of its important inner parts. If there is too much heat on a device it may not function as desired or worse still, stop working totally. In other words it is essential to have a skived heat sink performing here for everything going well.

This skived Heatsink design is also quite fascinating in itself. This unique configuration allows it to dissipate heat in a very short time with great effect. Excess heat produced by the device is exhausting out and cold air from outside enters inside. They push hot air out and let cold air inside the device which is how this process keeps your heat-generating device cool. Skived heat sinks can help ensure that your electronic devices perform as they should and do not simply overheat.

These are two key pieces of technology that help keep the skived heat sink cool down devices even more effectively. One of these innovations is known as skived fin technology. It involves a blade that beats back and forth to shear the metal plates like bread in different forms. This when long way in creating more open area for the movement of air through the fins of heatsink.

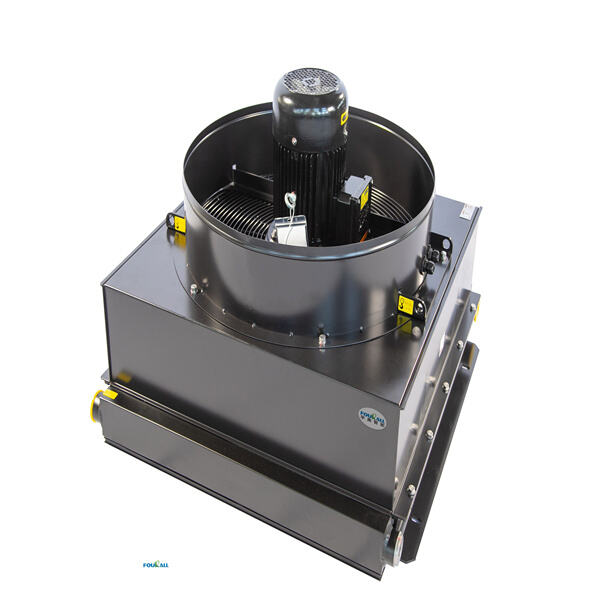

This unique technology also permits skived heat sinks to be manufactured in different configurations and sizes, just like the outdoor cooling system from NanJing Fourall. This allows them to fit into tiny inner workings of electronic devices. A larger surface area means more airflow can go, and thus the better it is at dissipating heat which translates to an improved cooling process. As airflow has increased, and devices have taken on different shapes that can be finned in various ways that we had not previously considered makes skived fins an exciting step forward for electronic cooling.

The smaller, snaggle-toothed blades featured on skived heat sinks make them an ideal choice for most cooling applications, same with NanJing Fourall's engine cooling system. Creating skived heat sinks involves a very precise and delicate process. They are also a better value to manufacturers, because they can be made for much cheaper. Similarly, this refinement also contributes to greater product quality as well. These favorable attributes is what make skived heat sinks a popular choice in most various industries around when designing electronic devices.

In addition to this, they are also made fit for high temperatures and rigorous environments since the skived heat sinks in particular involves an industrial process that allows all of its assemblies to meld with each other using only thermal paste or any medium suited for further pushing the product beyond limits, similar to the system of lubrication built by NanJing Fourall. This heat sink offers devices using it the flexibility to work fine under multiple scenarios regardless of how hot things get. Consequently, this design results in more durable products that are dependable.

Skived cooling solutions that are enhancing the performance of electronic equipment — including everything from desktop computers, to innovative robots, along with NanJing Fourall's product air in cooling system. This keeps the parts of these. devices within a safe operating temperature, allowing them to run for plenty long hours or years further than they would have in less extreme conditions And thanks to onboard storage, folks are still able to design better products that can run faster and longer as a result.

Fourall Company has classified its products into two categories: water cooling, lubrication and Skived heat sink for wind power applications. Water cooling system for large industrial and power applications. Wind power products are classified into five series that have more than 40 specifications. They include the wind power lubrication series WD Series, water-cooled OS Series FA/HC Filter element Series and patent-pending products, such as pressure follow-up temperature control FA/D series. We follow the standard management systems SO9001/14001/18001 and other standards to provide a comprehensive information system and a vertical after-sales system. This covers RD, Marketing, Manufacturing, Supply Chain, Quality Management and we are able to respond rapidly to the requirements of our customers and provide fast and efficient service. The business has offices located in Nanjing, Tianjin and Chengdu and has professional sales, technical, and support teams, to ensure that customers receive timely and reliable products as well as technical services.

Fourall team is Skived heat sink to research, development and production of components, fluids and products designed for use in the field of new energy large-scale power electronics. Our product line includes Lubrication systems; oil-cooling water-cooling and air cooling systems filters such as gear pumps; mechanical pumps; oil pipe; pressure-related TCV filtration; off-line bypass systems, and more.Fourall's highly-experienced RD team, with deep knowledge of industrial fluid applications and a decade or more of experience in wind energy fluid product application, can quickly determine and provide technological solutions. Fourall's high-tech processing technology, advanced testing equipment and quality assurance systems, as well as strict quality management methods are based on the most advanced testing and quality assurance systems.

Skived heat sink is a fluid technology company that specialises in the development of products and services used by many industries, such as photovoltaic and wind power transform stations and power transmission construction materials, and petrochemicals. We develop customized lubrication systems and cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We offer expert technical assistance and support for a variety of industries, while maintaining the highest standards in craftsmanship and quality management.Our technology is being used in Substation SVC Cooling System for Converters, cooling system for SVG Converters in Substation. Lubricating oil stations and cooling systems in the petrochemical and metallurgical industries. Building Material Industry Lubrication system and hydraulic system with cooling system.

We have successfully supplied lubrication systems with an overall capacity of Skived heat sink, and more than 3, 000 sets water cooling systems, and have supplied over 1000 wind farms. We have also served more than 300 owners of wind farms and wind turbine makers. We have developed a win-win relationship with many famous domestic producers of main components, including CSSC, NGC and DHHI. Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project in Danzhou, Hainan. Accepted in March 2024, over 30 sets were shipped by month's end, with 60 systems to be assembled by July 2024. Our innovative, patent-pending heat dissipation technology wind tunnel lab has enabled this achievement. This achievement shows Fourall's dedication to innovation and dedication to providing services and products of top quality, and aiding global developments in renewable energy.