We all have, surely at least once in your life you must've encountered a cooler that would just not work, identical to NanJing Fourall's product heat sink cooler. It could have failed at keeping stuff cold, or been noisy. From time to time, coolers can give up due to parts that are old or damaged and require replacement. But don’t worry. The right replacement parts can keep your cooler running smoothly and maintain it is longevity.

If you are unsure as to which parts need replacing, it is a wonderful thing to consult the owner's manual of your cooler. This guide can share what parts are crucial and how to repair them. It is then useful to go an ask and adult if you still have doubts or feel insecure. The fan, compressor at times the thermostat is some of those common parts that may need replacement. This will allow your cooler to keep beverages cold and run quietly.

A part of your cooler goes bad, do you know that replacing a single faulty spare part in the entire assembly will cost less then to replace it fully. That’s right. If your old cooler has problems, you can replace the parts that were wrong instead of throwing away a whole new one. By doing so, you are preventing yourself to buy a new cooler but still enjoy your cold drinks.

All the necessary cooler parts can be found in multiple online stores at a reasonable price, as well as the lincoln lubrication system innovated by NanJing Fourall. These stores have loads to choose from so you will be sure to find what your looking for it. As long as you purchase parts for the right model of cooler. Coolers are not universal, check compatibility is crucial. Overall, just make sure that if you are unsure about fixing it by yourself and have questions pose those to a grown-up. They may help you with the repairs, or at least let you know what steps to take.

Using a cooler with damaged components puts your equipment at greater risk of damage, and they will only go more downhill over time if things do not stop completely, same with NanJing Fourall's hydraulic power system. Ultimately, it will likely just cost you more in the long run when you may have to replace a cooler. This is why it a good choice to maintain your cooler and solve issues as you see them. In this manner, they save themselves from other worse issues and get that constant supply of cold drinks accomplished quickly.

Much has changed, but you will still be able to buy various replacement parts in order to add more functionality into your cooler, similar to the hydraulic clamping system by NanJing Fourall. One way to boost comfort and prepare for future energy rate hikes is buy conversion your old thermostat, so you can have the benefit of converting it into a computerized type. Or, you could fit a new LED light to help see in the dark when you go grab a cold one. The amount you can do with it is staggering. Buying a new color can provide extra motivation to get out there and drink up.

The nice thing about replacement parts is that they are made to install easily, identical to NanJing Fourall's product filter in hydraulic system. For the most part, as long as you follow instructions with precision then it is simply a matter of directing and fixing your cooler. You can insure that your cooler will last for a good long time and continue to function optimally by just using the right parts.

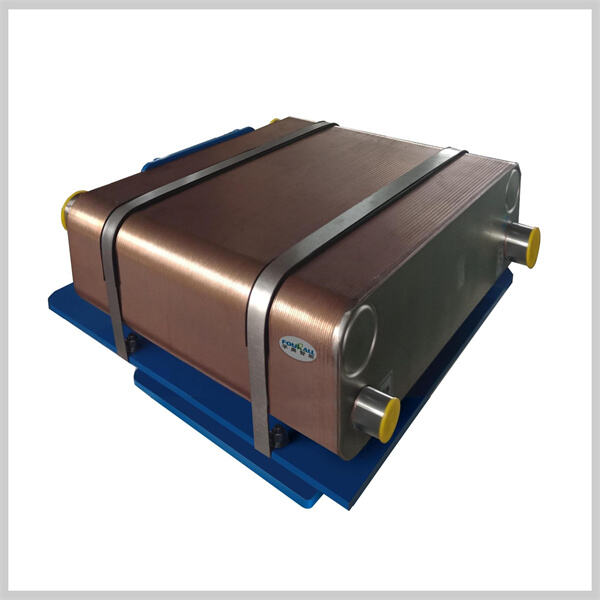

We've supplied lubrication equipment with a capacity of over 6 000 MW and more than 3000 water cooling units We also have served more than 1 000 wind farms and over 300 wind turbine makers Have formed a win-win collaboration with several renowned domestic main component manufacturers including CSSC Cooler replacement parts DHHI etc Just delivered water cooling system for Dongfang Electric's Wind Power Group's offshore 10MW project in Danzhou Accepted by March 2024 and delivered by April 60 systems will be in place by July Our advanced patented heat dissipation technology wind tunnel lab enabled this feat This achievement highlights Fourall's leading position in offshore water cooling technology and innovation We are committed to constant improvement and commitment to providing top-quality products and services to support the global development of renewable energy

Fourall team is focused on fluid technology and the products which are extensively used in Cooler replacement parts, photovoltaic power generation, power transmission transformation stations, metallurgy building materials, and petrochemical industries. We design and create custom cooling, lubrication, cylinder, and component systems for large-scale machines. We offer expert technical assistance and services to various industries, with high standards of workmanship and quality management.Our technology has been successfully used in the Photovoltaic power cooling system; solar thermal power hydraulic system; Substation SVC converter cooling system A cooling system to cool the SVG converters in substations. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries; Building Material Industry Lubrication system and hydraulic system with cooling system.

Fourall team is dedicated to research, development and production of fluid-related products and components to be used in the area of renewable energy and large-scale power electronics. Our product range includes air-cooling, oil-cooling, and air-cooling systems. Cooler replacement parts mechanical pumps, gear pumps oil pipes, pressure-following TCV, off-line bypass filters, and many more.With a highly skilled RD team with extensive industrial fluid application backgrounds, and over a decade of experience with wind power fluid product applications, Fourall is capable of efficiently identifying and delivering technological solutions. Fourall's advanced processing technology along with the latest testing equipment and quality assurance methods and quality management systems are built on advanced tests and quality control systems.

Fourall Company has categorizes its products into two categories namely water cooling, lubrication and hydraulic product to power wind turbines. Water cooling systems designed for Cooler replacement parts and power application. Within them, wind power items have been divided into five series, each with more than 40 specifications, including the wind power Lubrication WD series, water-cooled OS series and the FA/HC filter element series, patented products pressure following temperature control valve FA/D series, and off-line filtering FA/HU series. We adhere to the standard management system SO9001/14001/18001 and standards to provide an extensive information system as well as an integrated after-sales service system. This includes RD, Marketing Manufacturing, Supply Chain, Quality Management and we are able to react quickly to the demands of our customers and provide efficient and speedy service. The company is headquartered in Nanjing, Tianjin and Chengdu equipped with the latest technology, sales and service teams that give customers prompt and expert products and assistance.