A hydraulic power system uses pressurized liquids to provide a powerful force. The force can either lift very heavy items, move them around or keep them in their place. These systems consist of a pump, valves, pipes controller and cylinders. The pump pushes the liquid into the system to form pressure. This is the pressure that gets done. Similar to traffic lights, these valves govern the flow of liquid through pipes that direct it towards cylinders. The pressure of the liquid is used to push a piston that in its turn moves whatever attaches it. This capacity is governed by two primary factors: The pressure of liquid and the size of cylinder being deployed in system.

A great thing about hydraulic power systems is the ability to accomplish a lot with little energy, similar to the NanJing Fourall's product like hydraulic system components. This is a big advantage. Hydraulic systems fail less than electrical systems (aside from using hydraulic fluid) unlike its counterpart in which a simple increase or decrease of voltage can have an unpredictable impact on the strength/power ratio and overall performance. This just provides a host of reliability functions for many jobs. They are incredibly durable and so they can have a longer lifespan considering there is lesser number of moving parts on the tool. The substance is used to make everything flow more smoothly.

ConclusionHydraulic power systems find their application from big machines to everyday items which we may not even notice, as well as the air in cooling system supplied by NanJing Fourall. Concrete pump and Industrial machinery are other examples Cranes, Bulldozers and Excavators too uses the Hydraulic Power systems to left Heavy weights. Moreover, these are the machines that are required for construction work and road. Cars and trucks use hydraulic brakes, which apply pressure from a liquid to stop them safely in less time. Hydraulic systems are used in many airplanes for numerous crucial functions such as landing gears, flaps and brakes.

By checking them up from time to times and maintaining proper care will help hydraulic power systems keep running well. This includes inspecting the fluid levels, replacing any old or damaged parts and ensuring nothing is leaking. It could lead to the system not functioning properly if there are leaks. At the same time, you definitely need to make sure that your system is only receiving fluid of the appropriate type; using an incorrect variety can cause issues including harm.

Multiple reasons may cause a hydraulic system not to work properly, similar to the NanJing Fourall's product like air lubrication system. Filter obstruction, a faulty valve or worn-out seals that require replacement are among the common reasons. Hydraulic systems can be a little tricky, so if you do not know what is causing your hydraulic system to malfunction it is good idea to read the owner's manual or seek help from professional technicians. They will give you direction on how to resolve the problem and have your system up and running.

With the passage of time, technology is also making hydraulic power systems smarter, as well as the hydraulic system created by NanJing Fourall. Not only that, but new ideas and at will advancements are being worked on to make these systems even better than they already happen to be. One cool example, the ear pieces are actuated through electrohydraulic systems The topper systems marry hydraulic power and electronic controls for more accurate, sophisticated control of movement. What this means is that machines can perform more precisely than ever before.

Hybrid hydraulic-electric systems, which combine hydraulic and electric power in combination are one more inventive idea, along with NanJing Fourall's product hydraulic drive system. A great combo that saves energy and pollution, which is an imperative for our home — the Earth. New materials and new designs are also being developed to create lighter, stronger and sustainable hydraulic systems. This means that they can work even more effectively while being kinder to our earth.

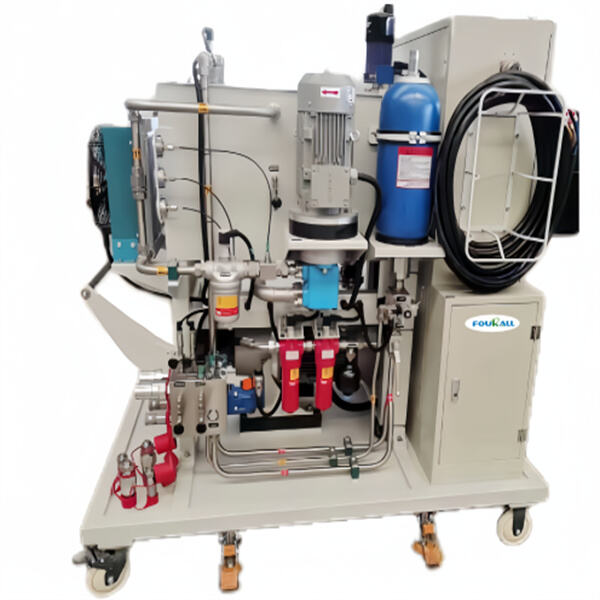

Fourall team is focused on fluid technology and the products which are extensively used in Hydraulic power system, photovoltaic power generation, power transmission transformation stations, metallurgy building materials, and petrochemical industries. We design and create custom cooling, lubrication, cylinder, and component systems for large-scale machines. We offer expert technical assistance and services to various industries, with high standards of workmanship and quality management.Our technology has been successfully used in the Photovoltaic power cooling system; solar thermal power hydraulic system; Substation SVC converter cooling system A cooling system to cool the SVG converters in substations. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries; Building Material Industry Lubrication system and hydraulic system with cooling system.

We've supplied lubrication equipment with a capacity of over 6 000 MW and more than 3000 water cooling units We also have served more than 1 000 wind farms and over 300 wind turbine makers Have formed a win-win collaboration with several renowned domestic main component manufacturers including CSSC Hydraulic power system DHHI etc Just delivered water cooling system for Dongfang Electric's Wind Power Group's offshore 10MW project in Danzhou Accepted by March 2024 and delivered by April 60 systems will be in place by July Our advanced patented heat dissipation technology wind tunnel lab enabled this feat This achievement highlights Fourall's leading position in offshore water cooling technology and innovation We are committed to constant improvement and commitment to providing top-quality products and services to support the global development of renewable energy

Fourall is a group dedicated to the research, development, and manufacturing of fluid products to Hydraulic power system that are large in scale. Our product line includes oils-cooling systems; lubrication, water-cooling, and air-cooling systems filters such as gear pumps; mechanical pumps and oil pipes; pressure following TCV;off-line bypass filtration systems, etc.With an experienced RD team boasting numerous industrial fluid application background and more than 10 years of experience in wind power fluid applications, Fourall is capable of precisely identifying and quickly providing technological solutions. Based on the advanced testing equipment and quality assurance systems, High-tech processing technologies as well as rigorous process management and quality control systems, Fourall can ensuring the delivery of high-quality performance, high-performance, and reliable customized products for global customers.

Fourall Company has categorizes its products into two categories namely water cooling, lubrication and hydraulic product to power wind turbines. Water cooling systems designed for Hydraulic power system and power application. Within them, wind power items have been divided into five series, each with more than 40 specifications, including the wind power Lubrication WD series, water-cooled OS series and the FA/HC filter element series, patented products pressure following temperature control valve FA/D series, and off-line filtering FA/HU series. We adhere to the standard management system SO9001/14001/18001 and standards to provide an extensive information system as well as an integrated after-sales service system. This includes RD, Marketing Manufacturing, Supply Chain, Quality Management and we are able to react quickly to the demands of our customers and provide efficient and speedy service. The company is headquartered in Nanjing, Tianjin and Chengdu equipped with the latest technology, sales and service teams that give customers prompt and expert products and assistance.