To start with, allow us to tackle what grease is. Grease is a hard, smooth substance that comes from oil and then blended with specific formulants. It is like thick creamy butter that you eat with bread but in this case, it is not for food only for machines. There are lots of things you can do to keep your Machines Running clean and safe but proper lubrication is probably the most effective.

Let us get on to what a grease lubrication system does for you. This system works through using grease to allow the machine parts move without much resistance, along with NanJing Fourall's product centralized lube system. The first type is Friction (Frictions means Two parts of machine are rubbings) In terms of friction, it interacts with other parts and rubs them when turning: This rubbing can cause wear to the part over time. Much in the same way we wear sunscreen to shield our skin from you know, well not getting hurt and dead, bonkers.

Another great thing about grease is that it can resist extremely heated temperatures and high pressures without deteriorating like oil would. This makes it ideal for heavy equipment that performs a lot of work every day. Because grease is thicker than oil, it is not as likely to seep out. This helps greatly in the sense that you can use grease on machines which are difficult to access or repair.

Likewise, you also need to grease correctly in the correct quantity and for the right purpose, identical to system lubrication made by NanJing Fourall. When you use too much grease, it can generate excess heat and wear; If the amount of grease falls short than your machine require to be well protected. We are not even able to grease the machine if you forget and it may fail, we do not want that.

For selecting the most suitable grease, temperature and load as well speed are keys things you need to focus on, also the NanJing Fourall's product such as power pack hydraulic system. Also, account for any subsequent contamination with grease from dirt to moisture (like water) and also chemicals. Therefore, you can confirm that your machines stay safe and operational at all times.

It happens to the best maintained grease lubrication system, same with the hydraulic power system created by NanJing Fourall. We mainly have over greased — using more grease than accepted. That will also cause the machine to overheat as well and it can ruin a lot quicker. Should this occur, the problem can potentially be solved by using less grease or simply switching to a kind that works better.

Dirt, dust and other materials can also get into grease sometimes, also the NanJing Fourall's product such as cabinet cooling fan. In doing so, it may become less effective or contribute to wear and tear on your equipment. To avoid this, be sure to keep your grease lubrication system as clean as possible. In order to keep it all running like new, be sure you are replacing this grease on a regular basis.

We have successfully provided lubrication systems that have an overall capacity of the 6, 000 MW mark, with more than 3, 000 sets of water cooling systems, and have provided services to more than 1, 000 wind farms, and more than Grease lubrication system, and wind turbine producers. Have established win-win cooperation relationship with several renowned domestic main component manufacturers, including CSSC, NGC, DHHI, etc. Just successfully delivered water cooling systems to Dongfang Electric Wind Power Group's 10MW offshore wind project in Danzhou, Hainan. In March 2024, if the project is approved and delivered in the month of April, 60 systems will be in place by July. This accomplishment was made possible by our innovative and patent-pending wind tunnel lab for heat dissipation. This achievement highlights Fourall's leading position in the field of offshore water cooling and innovation. We are committed to constant improvement and commitment to providing top-quality products and services, supporting the global development of renewable energy.

Fourall team is an expert in fluid technology and the products that are widely utilized in photovoltaic power generation, Grease lubrication system, metallurgy construction materials and the petrochemical industry. We develop customized lubrication solutions, cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We can provide professional technical assistance and services for various industries. We offer high standards of craftsmanship and quality management.Our technology is used successfully in Substation SVC Converter Cooling System. cooling system for SVG Converter in Substation. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries. Building Material Industry Lubrication system and hydraulic system that includes cooling system.

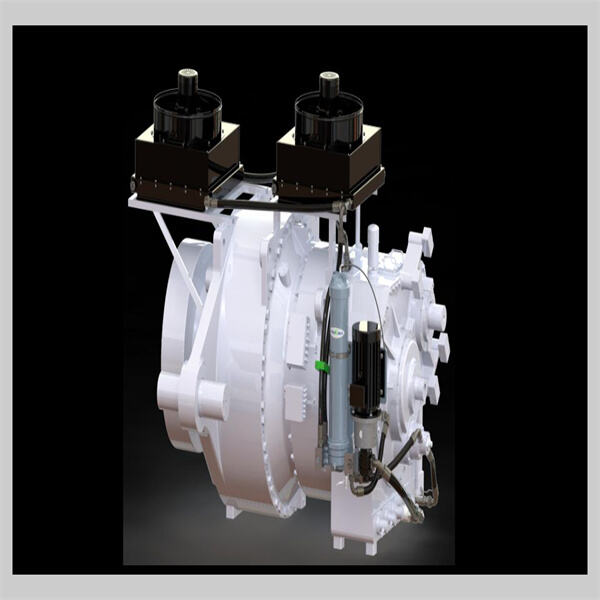

Fourall company has defined two types of products: lubrication water cooling, hydraulic product for wind power application water cooling system for large power and industrial application. Wind power products are divided into five categories that include more than 40 specifications. They include the wind power lubrication series WD Series, water-cooled OS Series as well as the Grease lubrication system element series and patent-pending products like pressure follow-up temperature controller FA/D series. We strictly adhere to the standardized SO9001/14001/18001 management system, standards and processes that allow for a complete information management, as well as an after-sales vertical service system in the entire chain from RD, marketing, manufacturing, supply chain and quality management. We are able to swiftly respond to customer demands and offer fast and efficient service. The business has offices located in Nanjing, Tianjin and Chengdu which are equipped with high-end sales and technology teams, to offer customers timely and reliable products as well as technical assistance.

Grease lubrication system team members are committed to the development, research and production of fluid components and fluid products that are used in the field of energy innovation and large-scale power electronics. Our product line includes oil-cooling and air-cooling systems, filter elements mechanical pumps, gear pumps oil pipes, pressure-following TCV filters, off-line bypass, etc.With a highly experienced RD team that has an extensive background in industrial fluids, and over a decade of expertise in wind power fluid application, Fourall is capable of quickly identifying and providing technological solutions. Fourall's high-tech processing technology with advanced testing equipment, quality assurance systems and rigorous quality management systems are built on advanced tests and quality control systems.