NanJing Fourall will teach you everything about hydraulic pump systemes! For example, a hydraulic pump gearbox is a very critical component on larger machines such as excavators, cranes and forklifts. These bots assist us with a lot of heavy lifting they pick up and carry load which is otherwise impossible for people. Hydraulic pump gearbox works on a specialized oil known as hydraulic fluid. What sets this hydraulic fluid apart from standard oil, however, is its ability to generate pressure that enables the various segments of the gearbox to operate smoothly and efficiently.

There are multiple advantages of employing hydraulic pump gearboxes in industrial machines. First, it allows the machines to lift very heavy objects with much less effort. The hydraulic fluid will build up pressure as it is forced through the gearbox. The pressure pushes the pieces of the gearbox which aids the overall machine movement. Try to lift something extremely heavy. That would be tough, without help! The hydraulic pump gearbox simply allows the machine to multiply its effort to move heavy objects.

First, it’s crucial to consider what function the machine will play. Some jobs require more power and speed than others. So if you are using a machine to lift something highly weight, you need a gearbox that delivers plenty of power But if the work is lighter, you may not need quite as much powe Well, understanding the function will help you select a product gearbox hydraulic pump that matches your needs.

Another consideration: the size and weight of your machine. It will require more powerful hydraulic pump gearboxes for a heavier machine to be able to do work efficiently. If the gearbox isn't powerful enough, the machine might not work well and that can be problematic. Always select a gearbox that is appropriate for the size & weight of your machine.

For hydraulic pump gearbox, hydraulic fluid is a generalised term for the type of fluids here. Big machines operate in a variety of materials and conditions, and these fluids are engineered to interact with them traducteurtexas.com/tourist-attraction-in-texas.html. Every hydraulic fluid has its own characteristics which makes it fit for different jobs.

Mineral oil, natural, based; water based fluids made from water; synthetic oil, man made; biodegradable oil safe for the environment. Different types of fluids have varying advantages, so it’s essential to select one specific to your machine’s needs. Choosing the appropriate hydraulic fluid will help the gearbox to continue functioning smoothly and efficiently.

Moving on, take a look at the size and weight of your machinery. If the machine is very large and heavy then its gearbox must be more powerful for the proper functioning of the machinery. Also, consider the environment in which your machinery will operate. If your machine will operate in extreme hot or cold weather, you need a hydraulic pump gearbox designed for this to work efficiently.

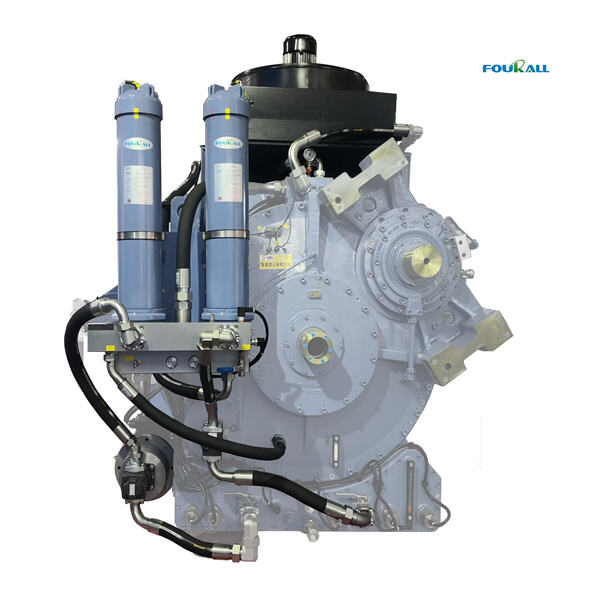

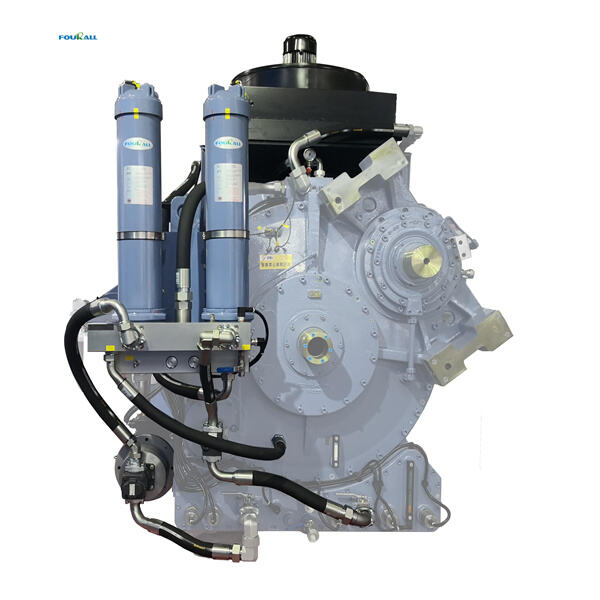

Fourall Company has classified products into two categories namely water cooling, lubrication and hydraulic product for wind power applications. Water cooling system for large industrial and power applications. Within them, wind power items have created five series that include more than 40 specification, including wind power Lubrication WD series, water-cooled hydraulic pump gearbox and FA/HC series of filter elements, patent-pending products for pressure following temperature control valve FA/D series and off-line filtering FA/HU series. We adhere to the SO9001/14001/18001 standard management system and the standards that provide a comprehensive information system and a vertical after-sales system. This includes RD Marketing, RD Supply Chain, Manufacturing, Quality Management, and we're able to respond rapidly to the requirements of our clients. We also offer fast and efficient service. The business has offices in Nanjing, Tianjin and Chengdu equipped with the latest sales, technology, and service teams to offer customers timely and high-quality products and services.

We have successfully supplied lubrication systems with an overall capacity of 6000 MW and more than 3 000 sets water cooling systems and have provided services to more than 1 000 wind farms We have also served more than 300 owners of wind farms and hydraulic pump gearbox We have built win-win relationships with several prominent domestic manufacturers of main parts such as CSSC NGC and DHHI Just delivered water cooling systems for Dongfang Electric Wind Power Group's offshore 10MW wind project located in Danzhou Hainan Accepted by March 2024 and delivered in the month of April 60 systems will be in place before July This accomplishment was made possible through our innovative and patented wind tunnel laboratory for heat dissipation This achievement is a testament to Fourall's commitment towards innovation and dedication to offering products and services of high quality while helping to support global renewable energy development

Fourall team is an expert in hydraulic pump gearbox and the products which are extensively employed in photovoltaic power generation, power transmission transformation stations, metallurgy, construction materials and petrochemical industries. We develop customized lubrication systems and cooling systems, hydraulic systems components, and cylinders for large-scale equipment. We can provide professional technical assistance and services to various industries with high standards of craftsmanship and quality control.Our technology is successfully utilized to Photovoltaic power inverter cooling system; solar thermal power hydraulic system Substation SVC converter cooling system and cooling system for SVG converter in substation. Industries of metallurgical and petrochemicals Lubricating stations for cooling and oil Building Material Industry Lubrication station hydraulic system cooling system, etc.

Fourall is a team dedicated to the research, development, and manufacture of fluids for large-scale power electronic applications. Our product range includes air-cooling, oil-cooling, and hydraulic pump gearbox. filters mechanical pumps, gear pumps, pipelines for oil, pressure-following TCV filters, off-line bypass, and more.With an experienced RD team boasting vast industrial fluid applications backgrounds, and over a decade of expertise in wind power fluid product applications, Fourall is capable of efficiently identifying and delivering technical solutions. Fourall's high-tech processing technology as well as the most advanced equipment for testing and quality assurance systems as well as rigorous quality management systems are built on modern tests and quality control systems.