Hydraulic Systems play an essential role in the operational efficiency and uptime of big machinery. The hydraulic pump system is one of the key components. One of the most important things a gearbox lubrication system does is provide fluid for the hydraulic system. This fluid is highly essential so that the machines work perfectly. Examples of heavy machinery that needs a gearbox pump to work are excavators, bulldozers and cranes. Most construction and many industrial applications would come to a standstill if not for these pumps.

Gearbox Pump – Responsible for the replacement fluid supply, ensuring normal flow of steady and consistent fluid. A constant stream like this is important to provide the maximum running capacity that a machine can offer. This way the hydraulic components operate properly and efficient, tool processing speed is also increase by a good amount. The machine is no longer limited by the cooling system and can do more work in less time. This enables work to be done rapidly, instead of having a pump inefficient in function. This is especially crucial in busy workplaces where the productivity of any given operation can ultimately lead to whether or not a project gets done on time, and with a gearbox pump that works as it should you are simply able to move along things much faster than what would be possible otherwise.

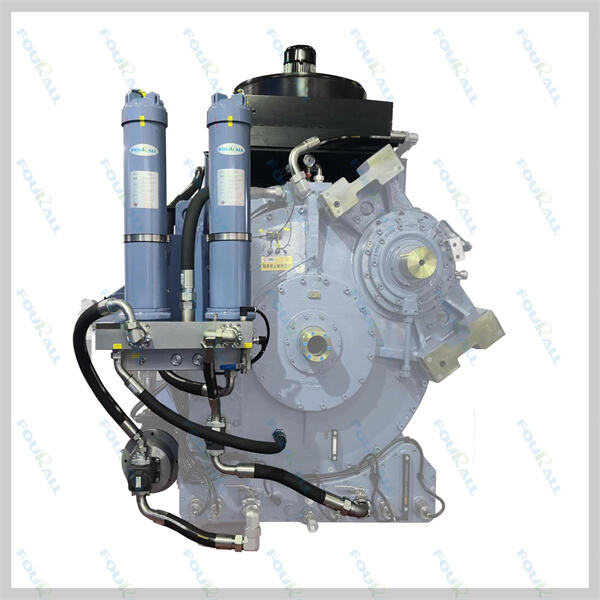

There are various types, and sizes of gearbox pumps that can use. This is because each device needs its particular weight fixing. To ensure that the machines can be used, it is critical to select an appropriate size of gearbox pump according to different types of hydraulic system. The size and the function of a machine determine the type of pump it requires. An example is the variety of gearbox pumps developed with different types such as helical, worm, spur, helical-bevel or planetary gearboxes. As there are different types of gearbox pump, and each is for use in specific jobs it is important to choose the right one.

As with any machinery, the gearbox pump requires regular servicing and upkeep. Proper caring for the pump will prevent damage that can cause it to malfunction. Maintenance: Regular maintenance of the gearbox pump is necessary for it to run safely and efficiently. This requires regular lubrication of the pump and to service it periodically. When it breaks, the entire pump unit must be replaced—which often costs thousands of Rands. The gearbox pump failure can have catastrophic impacts on an equipment, as the complete machine is at a halt.

Finally, it is clear that gearbox pumps are an essential element of heavy machines. These hydraulic systems would not function, and the machines could not do what they are capable of doing. Heavy equipment can be pricey and you need to makesure that it remains in functioning problems. For most with work to do and businesses to run being effective is not only important, its essential. This is why gearbox pumps are an incredibly important part of hydraulic systems for all large machinery.