Have you ever ridden a bicycle before? You understand worlds better how crucial it is to continue turning the wheels. Lubrication is very necessary in this and even for machines that works on air power called pneumatics. The way oil helps keep your bike chain in tip top condition is in the same manner that lubrication aids pneumatic machines to have a better performance and increase its lifespan.

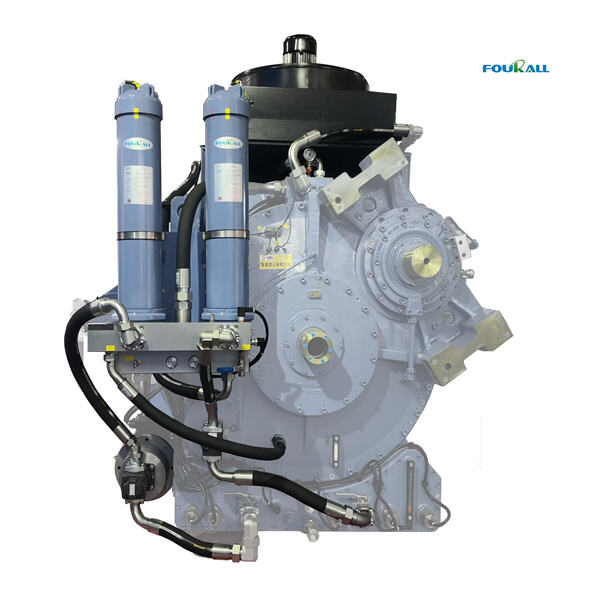

A specialized job performed by the pneumatic lubrication system. It applies oil or lube on the components that move in your pneumatic gear. Like putting oil on your bike chain so it will run smooth. This NanJing Fourall lubrication pneumatic system keeps everything well-lubricated, which means that parts do not wear out too soon and the machine operates as it is supposed to.

Machines are operated through the moving parts and lubrication helps all these different parts in operating without rubbing against each other too much. When parts are rubbed together extensively, they face breakage and malfunction. Consider it akin to: if eating good, wholesome food sustains and energizes our bodies the same can be said for lubrication helping keep our machines fields in tip-top condition.

Be it anything, if machines are mechanically poor, they will not be able to work as long as they should. They may get louder, wobble or even just stop functioning altogether. This is why pneumatic machines need to remain lubricated at all times. They will perform at their very best and longer when they have the proper lubrication.

Altogether, an automatic pneumatic lubrication system is necessary if you care about getting more life out of your machines and smoother operation. This NanJing Fourall lubrication system sends a constant stream of oil or grease to any part that moves. It means: Do not worry about where to put the right amount of topping. Ensuring optimal everything runs just like a well-oiled system, is the perfect pneumatic lubrication system. This will help avoid issues that may lead to your appliances going down or taking longer in function.

The lubricant must be a type which is ideal to use. Either type of oil/grease can be used (be careful not to use too much) And if you overuse lubricant, it itself can act as a dust and dirt magnet which may give problems later on. Do make sure to follow the instructions of your sewing machine's manual for proper NanJing Fourall system lubrication practices and oiling.

How frequently you need to apply it, and how lubrication will depend on the frequent use of your machine. If you do not use lubricant generously the parts will wear away too soon. But, conversely to using too little amount it could create other sorts of issues such as clogging up the appliance. But necessary is only finding a balance.

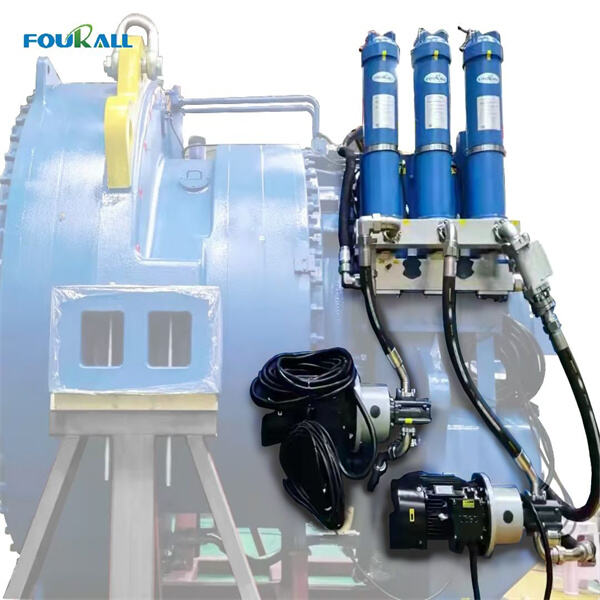

Pneumatic lubrication system company has categorized two categories of products: lubrication as well as water cooling. The company also has a the hydraulic product designed for wind power use water cooling system for large power and industrial applications. Wind power products can be classified into five categories that include more than 40 specifications. These include the wind power lubrication WD Series water-cooled OS Series as well as the FA/HC filter element series and patented products such as pressure follow-up temperature controller FA/D series. We follow the standard management system SO9001/14001/18001 and other standards to provide an extensive information system as well as a vertical after-sales program. This includes RD, Marketing Manufacturing, Supply Chain, Quality Management and we are able to respond rapidly to the requirements of our clients and provide fast and efficient service. The company has offices located in Nanjing and Tianjin as well as a an experienced team of sales, technical and service personnel to provide customers with quick as well as professional technical and product support.

Pneumatic lubrication system team members are committed to the development, research and production of fluid components and fluid products that are used in the field of energy innovation and large-scale power electronics. Our product line includes oil-cooling and air-cooling systems, filter elements mechanical pumps, gear pumps oil pipes, pressure-following TCV filters, off-line bypass, etc.With a highly experienced RD team that has an extensive background in industrial fluids, and over a decade of expertise in wind power fluid application, Fourall is capable of quickly identifying and providing technological solutions. Fourall's high-tech processing technology with advanced testing equipment, quality assurance systems and rigorous quality management systems are built on advanced tests and quality control systems.

We have installed lubrication equipment with capacities that exceed the 6, 000 MW mark, with more than 3, 000 sets water cooling systems, and been able to serve more than Pneumatic lubrication system, over 300 wind farm owners, and wind turbine manufacturers. We have developed win-win relationships with several prominent domestic manufacturers of main components, including CSSC, NGC and DHHI. Just received a water cooling system for Dongfang Electric Wind Power Group’s 10MW offshore project in Danzhou. Accepted in March 2024, over 30 sets were shipped by month's end, with 60 units to be assembled in July 2024. Our advanced, patented heat dissipation performance wind tunnel lab was the catalyst for this achievement. This achievement shows Fourall's dedication to innovation and dedication to offering products and services of high quality, while supporting global renewable energy developments.

Fourall team is an expert in Pneumatic lubrication system and the products which are extensively employed in photovoltaic power generation, power transmission transformation stations, metallurgy, construction materials and petrochemical industries. We develop customized lubrication systems and cooling systems, hydraulic systems components, and cylinders for large-scale equipment. We can provide professional technical assistance and services to various industries with high standards of craftsmanship and quality control.Our technology is successfully utilized to Photovoltaic power inverter cooling system; solar thermal power hydraulic system Substation SVC converter cooling system and cooling system for SVG converter in substation. Industries of metallurgical and petrochemicals Lubricating stations for cooling and oil Building Material Industry Lubrication station hydraulic system cooling system, etc.